Precision grinding is a specialized machining process designed to achieve exceptionally tight tolerances and superior finishes on parts. This method falls under the broader category of cutting and metal-cutting processes used in manufacturing and tool-making. In production settings, grinding is particularly valuable for making fine, shallow cuts that enhance the shape, dimensions, and surface finish of various materials.

In industries where precision is paramount and errors can significantly impact production, precision grinding is crucial. This technique addresses the challenges of achieving stringent engineering tolerances and resolving finishing issues that are common in manufacturing. Precision grinding effectively removes material to produce custom parts that meet exact specifications for dimensions and surface quality.

High precision grinding takes this a step further by machining workpieces with exceptional accuracy. It can achieve tolerances as precise as +/- 26 microns to +/- 2.6 microns in diameter and +/- 2.5 to 0.4 microns for roundness. Additionally, this method can reach very specific surface finishes, maintaining a tolerance range of 0.40 to 1.6 microns. This level of precision ensures that components are manufactured to the highest standards required by the most demanding applications.

Advantages of Precision Grinding in Manufacturing

Precision grinding provides several key advantages in the manufacturing process. Explore these benefits below:

Economic Efficiency and Precision

High precision grinding not only ensures exceptional accuracy but also serves as an economical solution for manufacturing various components. Many metal manufacturers prefer this method for its ability to replicate precise dimensions of complex parts consistently within a narrow variance range. Additionally, this grinding technique enhances the productivity of manufacturing precise components, streamlines quality control, and maintains consistency across production batches. Collectively, these attributes make precision grinding a highly efficient process in manufacturing.

Dependable Machining Option

Precision grinding is often the preferred process chosen by skilled machinists when alternative methods such as milling and turning are unsuitable. This preference typically arises due to several factors:

The specific type of material being used;

The required quality of the surface finish;

The necessity to manufacture parts with small diameters and stringent tolerances.

Varieties of Precision Grinding Techniques

Precision grinding processes are diverse, each designed to achieve the desired surface finish and dimensional accuracy for various components. The choice of a specific grinding operation depends on the part’s size, shape, desired finish, and required production rate. Here are some of the most prevalent types of precision grinding:

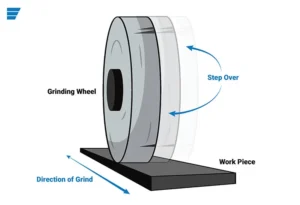

1. Surface Grinding Surface grinding is utilized to create a smooth finish on flat surfaces, enhancing their appearance or functionality. This process involves a rotating abrasive wheel that removes small chips or excess material from a workpiece’s surface. The surface grinding setup typically includes a chuck and a magnetically equipped table to secure the material in place.

With the integration of CNC technology, surface grinding can achieve automated material removal, facilitating high-volume production with consistent quality. This method is particularly effective for ensuring perpendicularity of the ends of a metal part to its external diameter, or achieving parallelism and squareness in cubic parts.

Surface grinding is chosen when CNC turning and milling do not provide sufficient precision, achieving production tolerances and surface finishes down to 0.4 microns. The outcome of surface grinding can vary based on several factors, including the wheel’s speed, size, and abrasive material, as well as the workpiece’s material properties.

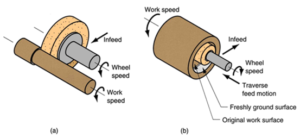

2. Cylindrical Grinding Cylindrical grinding, or center-type grinding, is applied to cylindrical surfaces and shoulders of workpieces. It includes a grinding wheel, a chuck, and two centers to secure the workpiece. Many cylindrical grinders also feature a swivel to accommodate the creation of tapered pieces.

2. Cylindrical Grinding Cylindrical grinding, or center-type grinding, is applied to cylindrical surfaces and shoulders of workpieces. It includes a grinding wheel, a chuck, and two centers to secure the workpiece. Many cylindrical grinders also feature a swivel to accommodate the creation of tapered pieces.

In cylindrical grinding, the workpiece is held between centers and rotated, interacting with the grinding wheel moving at a different speed. This process is suitable for achieving smooth finishes on round objects, with standard precision tolerances typically around 1.3 microns for diameter and 0.25 microns for roundness. Cylindrical grinding is divided into two main types:

Internal Diameter Grinding (ID): This technique focuses on removing material from the internal diameter of tubes and other features, often used alongside honing for achieving smooth finishes and tight tolerances.

External Diameter Grinding (OD): OD grinding shapes the external surface of a workpiece, suitable for various shapes like cylinders and cams, provided they have a central axis large enough for rotation.

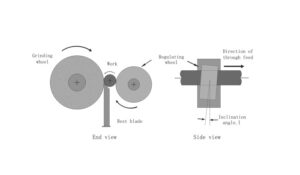

3. Centerless Grinding Centerless grinding is used for finishing the external diameter of small, cylindrical parts, often to enhance the precision of turned components. Unlike traditional grinding methods, centerless grinding does not use centers or chucks but instead relies on a rest blade for support.

3. Centerless Grinding Centerless grinding is used for finishing the external diameter of small, cylindrical parts, often to enhance the precision of turned components. Unlike traditional grinding methods, centerless grinding does not use centers or chucks but instead relies on a rest blade for support.

This method involves two wheels: the abrasive grinding wheel and a slower-moving regulating wheel. The unique setup allows for the grinding of very small parts, as the workpiece passes between the two wheels without additional support, guided only by the critical angle of alignment between them.

Utilization of Precision Grinding in Manufacturing Sectors

Precision grinding is commonly employed as a final machining step across various manufacturing industries, ensuring parts are produced with high accuracy and efficiency. This technique is integral in sectors such as automotive, aerospace, bearings, electronics, and medical devices. Below are some typical applications of precision grinding:

Micro-finishing of Flat and Cylindrical Surfaces: This application involves refining the surfaces to achieve a high degree of smoothness and dimensional accuracy, essential for critical components.

Machining of External Circles, Holes, and Hole Systems: Precision grinding is used to shape and finish the outer contours and internal features of parts, ensuring they meet strict specifications.

Grinding of Bearing Surfaces: Bearings require extremely smooth and precise surfaces to function correctly, and precision grinding is key to achieving these characteristics.

Precise Machining of Aerospace Components: This includes the detailed shaping and finishing of fasteners, tubes, rods, wires, and bladed tools, which are critical for the performance and safety of aerospace hardware.

Fundamentals and Safety Guidelines for Using Precision Grinding Machines

Precision grinding machines operate by employing a rotating grinding wheel made up of abrasive particles that methodically remove material from workpieces. These machines are powered by electric motors that transfer motion to the grinding wheel via a belt and pulley system. The speed of the grinder motors can range from 150 to 15,000 rpm, depending on the specific requirements of the grinding task.

Precision grinding machines operate by employing a rotating grinding wheel made up of abrasive particles that methodically remove material from workpieces. These machines are powered by electric motors that transfer motion to the grinding wheel via a belt and pulley system. The speed of the grinder motors can range from 150 to 15,000 rpm, depending on the specific requirements of the grinding task.

Safety Measures for Operating Grinding Machines

To ensure safe operation while using a grinding machine, adherence to several safety precautions is essential. Personal Protective Equipment (PPE) must be worn at all times to protect against sparks and debris generated during grinding. This protective gear includes aprons, safety glasses, gloves, dust masks, hearing protection, and safety boots.

Key safety tips for using grinding machines include:

Ensuring the Grinding Guard is Securely Fastened: This helps prevent particles from flying off and causing injury.

Using the Appropriate Wheel for Each Task: Different materials and operations require specific types of grinding wheels.

Proper Assembly and Tightening of Flanges and Other Components: This ensures that all parts of the grinding machine are stable and secure, reducing the risk of malfunction.

Securing the Workpiece Firmly: A well-secured workpiece prevents movement during grinding, which can lead to inaccuracies or accidents.

Adjusting the Grinding Speed Appropriately: The speed should match the type of material and the precision required for the job to optimize performance and safety.

Maintaining a Clean Work Area: A tidy environment reduces the risk of accidents and improves operational efficiency.

Receive Top-Tier Precision Grinding Services at AS Prototypes

Precision grinding is a vital service in numerous industries today. While some manufacturing facilities have the capability to perform this service in-house, others prefer to partner with specialists that offer dedicated precision grinding services.

Precision grinding is a vital service in numerous industries today. While some manufacturing facilities have the capability to perform this service in-house, others prefer to partner with specialists that offer dedicated precision grinding services.

At AS Prototypes, we are equipped with the latest on-site precision machining technologies and tools necessary to manage your projects effectively. Our team comprises highly experienced professionals who are adept at meeting your specific design requirements. We are committed to delivering high-quality, precise, durable, and cost-effective precision machined parts, regardless of the order volume.

For personalized support services, contact us today. We guarantee a response within 24 hours, ensuring that your needs are promptly and efficiently addressed.

FAQ

What is the precision of a grinding machine?

The precision of a grinding machine can vary depending on the specific application it is used for. Typically, for rough grinding operations where large amounts of material are removed quickly, precision may be less of a concern. However, when used as a finishing process, grinding machines can achieve accuracies up to +/- 0.0025 mm. This level of precision is often necessary when the machine is used to remove very small amounts of metal, typically between 0.25 and 0.50 mm in depth.

What are the typical cutting speeds for a grinding machine?

Cutting speeds for grinding machines can vary widely based on the operation being performed. The optimal cutting speed is generally between 20 and 25 meters per second (m/s). For most surface grinding tasks, speeds of 30 to 35 m/s are commonly used. However, it is possible to perform grinding at much lower speeds, even below 1 m/s, especially with specialized equipment like a 0.2 mm grinding pin, which at 40,000 RPM achieves a cutting speed of around 0.4 m/s.

Additionally, high-speed grinding operations may utilize special wheels designed to operate at speeds up to 100 m/s. High-speed grinding is often more productive and efficient, and it can also extend the life of the grinding wheel by reducing the load on individual grains.