Guide to Stereolithography (SLA)

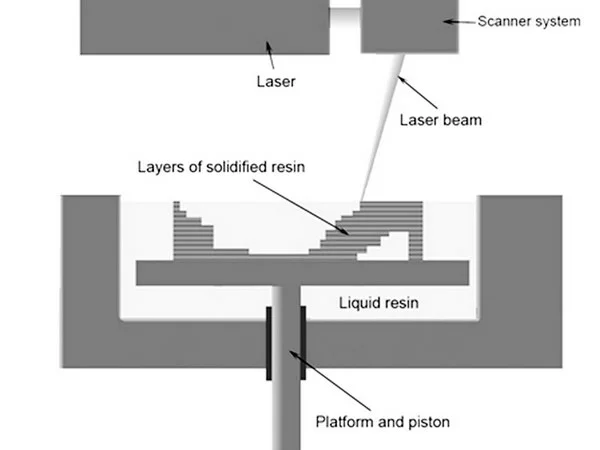

Stereolithography, or SLA, is a form of additive manufacturing that uses ultraviolet (UV) light to cure layers of photopolymer resin in a vat. This technology is renowned for its high-resolution capabilities, surpassing many other 3D printing methods in its ability to produce parts with intricate details and smooth surface finishes. SLA 3D printing is extremely adaptable, making it ideal for both prototyping and production. It is commonly used to create parts that are comparable to those made through injection molding.

What is Stereolithgraphy?

Stereolithography (SLA) is a 3D printing process used to create concept models, cosmetic prototypes, and complex parts with intricate geometries. It’s an additive manufacturing technology that forms parts by curing thermoset resin with a UV laser. A wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SLA.

At AS Prototypes, we specialize in Stereolithography (SLA), a technology renowned for its high precision and accuracy, making it ideal for applications where form, fit, and assembly are crucial. Our SLA processes achieve tolerances tighter than 0.05 mm and provide the smoothest surface finishes in the additive manufacturing industry.

At AS Prototypes, we specialize in Stereolithography (SLA), a technology renowned for its high precision and accuracy, making it ideal for applications where form, fit, and assembly are crucial. Our SLA processes achieve tolerances tighter than 0.05 mm and provide the smoothest surface finishes in the additive manufacturing industry.

SLA is not only about precision; it also excels in speed, making it perfect for producing a range of functional prototypes and immediate access to detailed casting patterns. This combination of rapid turnaround and exacting detail ensures that SLA is an outstanding tool for prototype evaluation, allowing for early detection and correction of design flaws, potential manufacturing conflicts, and other production issues. This is crucial in streamlining the path from concept to production, particularly in scenarios where characteristics akin to parts typically machined from materials like polypropylene or ABS are needed for low- to mid-volume production.

Moreover, SLA’s versatility extends to cost efficiency, as it conserves materials by retaining unused resin in the vat for future use, eliminating the need for costly retooling during customization or design modifications.

Post-processing of SLA parts at AS Prototypes opens up further possibilities. Our parts can undergo various finishing techniques such as vapor honing, bead blasting, or sandblasting, enhancing their aesthetic and functional qualities. Additionally, we offer electroplating services, including nickel plating, which not only strengthens the parts but also enhances their electrical conductivity and dimensional stability in humid conditions.

At AS Prototypes, we leverage SLA technology to its fullest potential, ensuring our clients receive components that meet the highest standards of precision, efficiency, and versatility.

SLA, with its unparalleled surface smoothness, makes this advanced technology ideal for a variety of applications.

General

- Design validation models to assess appearance and for proof-of-concept demonstrations

- Functional prototypes and models specifically for form and fit evaluations

- Models suitable for wind-tunnel testing

- Products and components that require high transparency and clarity

- Intricate assembly models

- Components designed for use under-the-hood

- Personalized products tailored through mass customization

Tooling and patterns

- Patterns for investment casting

- Sacrificial patterns used in metal casting processes

- Customized jigs and fixtures for assembly

- Production of tools, molds, and dies

- Master patterns for cast urethane and vacuum casting processes

Biocompatible materials

- Surgical instruments and guides

- Dental devices

- Hearing aid components

Our Accura SLA resins are engineered to deliver the most precise prototypes for design validation, ensuring an accurate fit and form prior to production. These resins are favored for their high precision and superior surface finish, making them ideal for designer models, engineering tests, and master patterns for silicone and rubber molding.

The SLA materials we offer encompass a broad spectrum of mechanical properties, enabling the production of parts that closely mimic those made from injection-molded ABS or polypropylene. This makes them perfect for applications requiring snap-fit components, automotive design elements, and master patterns. Additionally, we provide SLA materials designed for high-temperature environments and those that need to maintain clarity with polycarbonate-like characteristics.

Our selection of SLA materials also includes options that are biocompatible, catering to a wide array of medical uses such as surgical instruments, dental devices, and hearing aids. For specialized applications like sacrificial investment casting, we offer specifically formulated resins that produce minimal ash and maintain high dimensional accuracy, while being designed for easy expendability.

Rigid

Aesthetic and physical properties comparable to injection-molded ABS.

Tough & Durable

Appearance and texture similar to polypropylene

Clear

Featuring the industry-leading clear material that mimics polycarbonate properties.

Castable

Resins tailored for expendability, specifically developed for QuickCast® sacrificial patterns used in investment casting.

High Temperature

Capable of withstanding heat deflection temperatures exceeding 215°C (419°F), these materials deliver outstanding performance in extreme conditions.

Specialty Materials

Featuring specialized options for jewelry casting and the production of dental models.

Why choose AS Prototypes

for your SLA projects?

Unrivaled Accuracy and Precision

SLA 3D printers from AS Prototypes are renowned for their capability to produce highly detailed parts, from tiny components a few millimeters in size to large items up to 0.8 meters long. Despite the size variations, all parts maintain exceptional resolution and precision. This technology ensures that even the largest parts exhibit minimal shrinkage or warping, maintaining high accuracy from end to end.

Trusted Production Quality

Over the last decade, AS Prototypes has introduced 5 advanced SLA printers, each surpassing its predecessors in performance and quality. Our printers utilize dual laser spot sizes for each layer, which allows for the creation of parts with the finest surface finishes and intricate details without compromising speed. This approach optimizes throughput and consistently delivers exceptional detail in every print.

Extensive SLA Materials Range

For over ten years, AS Prototypes has worked closely with our clients, developing a diverse array of more than 30 tailored SLA materials to meet specific application needs. Our expansive material portfolio is designed to meet precise mechanical specifications. We encourage you to explore our offerings or consult with our expert team to find the ideal material for your specific project requirements.

Maximize Productivity 24/7

AS Prototypes achieves unparalleled productivity with the industry’s fastest 3D printing technology, ideal for extensive and high-volume production runs. Our printers feature quick-change material delivery modules that facilitate uninterrupted operation, significantly enhancing your manufacturing workflow. This system is designed to keep your production moving smoothly and efficiently at all times.