Rapid CNC Machining Services At AS Prototypes

At AS Prototypes, we offer an extensive array of CNC machining services, including CNC Milling, CNC Turning, 5-Axis CNC Machining, Precision EDM, Precision Grinding, and Swiss-Type Machining. Our adherence to ISO 9001 standards ensures a rigorous production process, backed by our extensive expertise and state-of-the-art CNC machinery. This combination guarantees that your parts are manufactured accurately and efficiently on the first attempt and consistently thereafter.

CNC Milling at AS Prototypes

CNC milling is a subtractive manufacturing process that uses a rotating cutting tool to remove material from a workpiece. This versatile method can machine various plastic and metal materials into precise components with tolerances as tight as +/- 0.03 mm. It is particularly effective for industries requiring high-precision parts and is also an excellent choice for mold making.

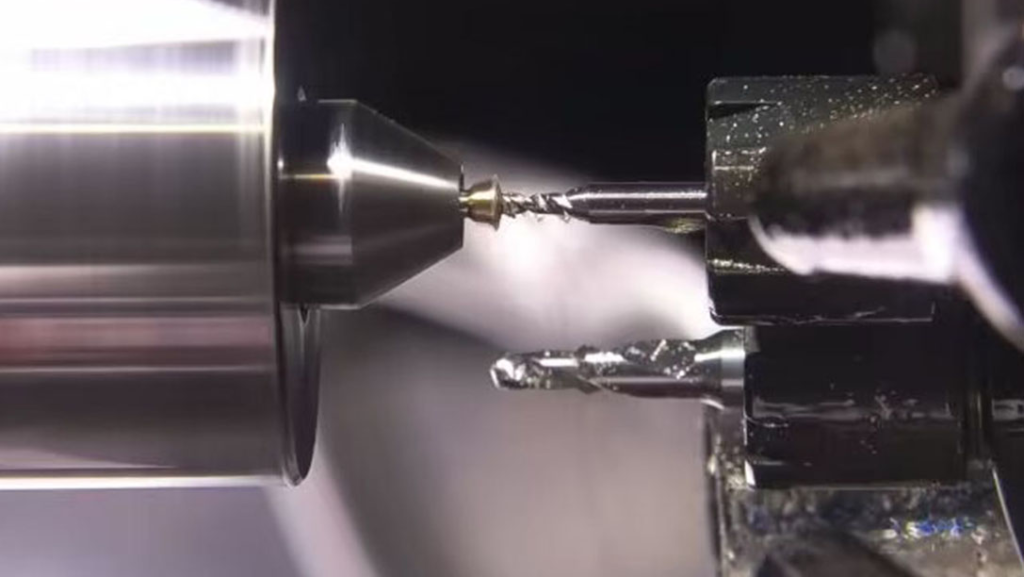

CNC Turning at AS Prototypes

CNC turning involves a cutting tool interacting with a rotating workpiece to shape cylindrical forms and achieve intricate details. This process can produce complex geometries and internal bores, with precision up to +/- 0.01 mm tolerance, suitable for various applications.

5-Axis CNC Machining at AS Prototypes

5-axis CNC machining enhances the capability to produce complex parts by processing up to five sides in a single setup. This efficiency leads to better utilization of machinery, fewer setups, reduced cycle times, and enhanced part quality, making our CNC operations more cost-effective across a broader range of projects.

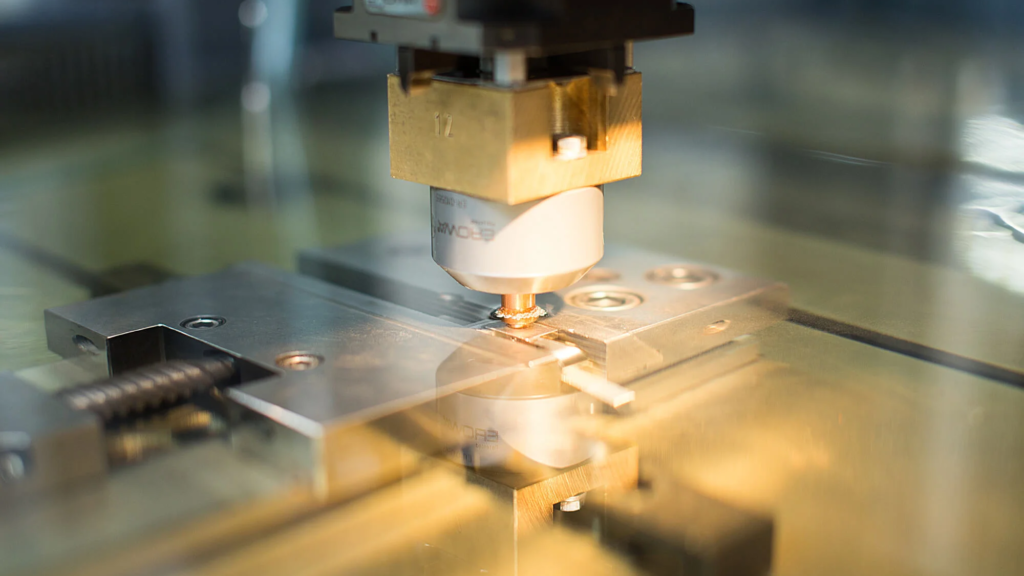

Precision EDM at AS Prototypes

At AS Prototypes, we specialize in ultra-precision machining for projects demanding tolerances as strict as ±0.005 mm or finer. Utilizing state-of-the-art EDM (Electrical Discharge Machining), wire EDM, and precision grinding technologies, we achieve superior accuracy and repeatability, even in the most intricately designed parts.

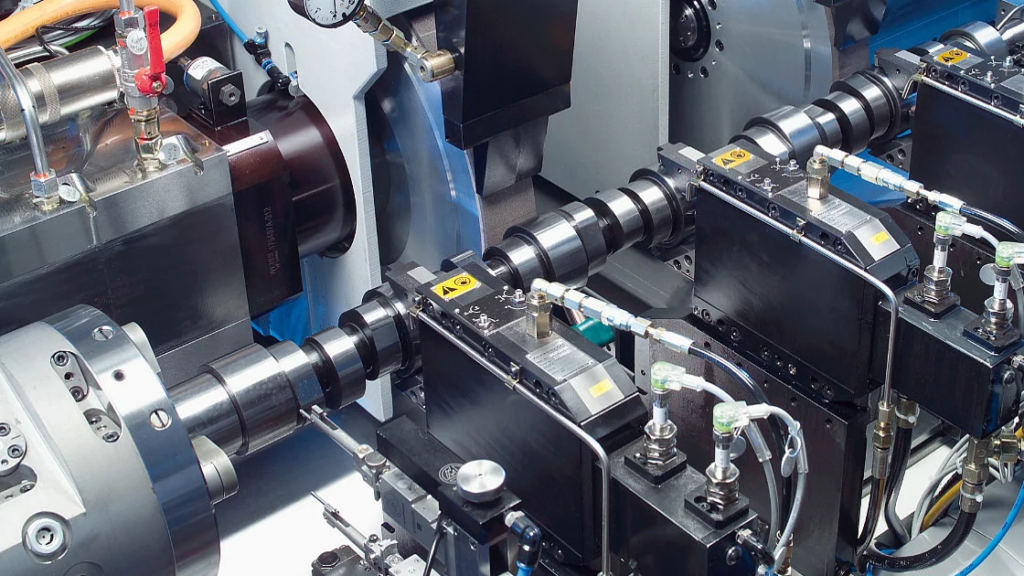

Precision Grinding at AS Prototypes

Precision grinding is a machining technique that employs abrasive instruments to remove minimal material quantities from a workpiece. This process is known for its high accuracy, producing components with stringent tolerances and a refined surface finish. Precision grinding can be applied to a diverse range of materials, such as metals, plastics, and ceramics.

Swiss-Type Machining at AS Prototypes

AS Prototypes specializes in Swiss-type turning, delivering ultra-precision micro-component manufacturing for industries like medical devices and aerospace. We handle complex machining needs with advanced precision technology, ensuring exceptional precision and quality.

CNC Machining Service

Looking for a reliable and swift CNC machining supplier for your project? AS Prototypes stands as a leading expert in CNC machining in China, specializing in both prototype development and the production of end-use machined parts.

CNC Machining Materials & Finishes

AS Prototypes offers a comprehensive selection of materials suitable for CNC machining, accommodating over 30 engineering-grade plastics and metals. This versatility ensures that our clients can select the optimal material for their specific application needs. In addition to our material variety, we provide a wide range of surface finishes to enhance both the appearance and functionality of CNC machined parts.

Plastics: Our offerings include ABS, PC, ABS+PC, PMMA (Acrylic), PA (Nylon), PA+GF30, POM (Acetal / Delrin), PP, PVC, HDPE, PPS, PEEK, PEI (Ultem), Teflon, Bakelite Resin, and Epoxy Tooling Board.

Metals: We machine parts from Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, and Zinc Alloy.

Finishes: AS Prototypes provides a full suite of CNC machining surface finishes to meet any design’s aesthetic and functional demands. Our finishing techniques include sanding, sandblasting, mirror polishing, painting, printing, laser etching, anodizing, electroplating, nickel plating, chrome plating, and powder coating.

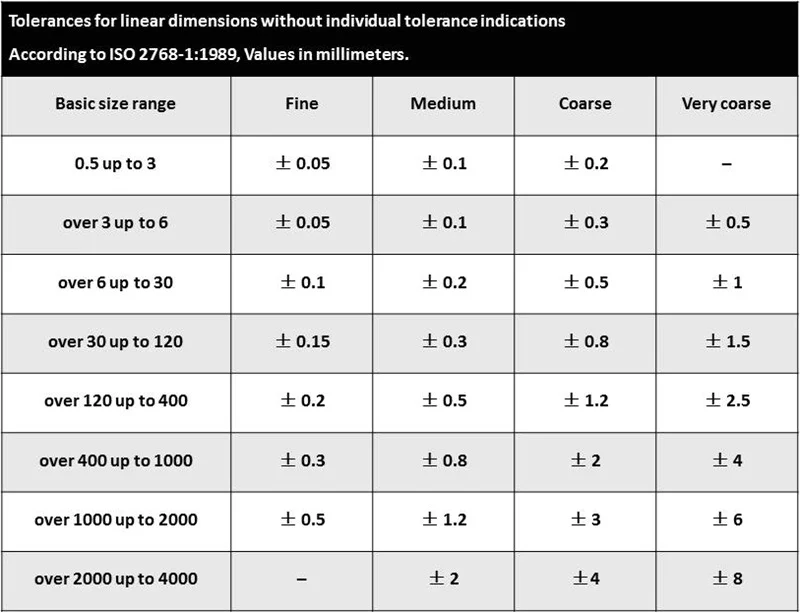

CNC Machining Tolerances

At AS Prototypes, we adhere to stringent tolerance standards for high precision in machined parts. For plastics, we apply ISO 2768 (medium) and for metals, ISO 2768 (fine). Typically, our CNC machining achieves tolerances from ±0.01mm to ±0.03mm. For even tighter tolerances, we utilize advanced EDM (Electrical Discharge Machining) and precision grinding, which can achieve superior accuracy. Clients requiring these high levels of precision should provide detailed 2D drawings with all necessary specifications. Our engineering team reviews these to ensure we meet your project’s critical dimensional tolerances, delivering precision tailored to your needs.

A Quick Guide To Designing CNC Machined Parts

Designing CNC machined parts efficiently can significantly reduce manufacturing costs and time. Here are key strategies to optimize your designs by simplifying machining requirements and enhancing part manufacturability.

Maximize Internal Radii To facilitate easier and faster machining, design internal corners with the largest possible radius. This approach minimizes the need for smaller tools, which are slower to use. Ideally, internal radii should be larger than one-third of the cut’s depth. Standardizing the radius across all internal edges allows the use of the same milling tool throughout the process, enhancing efficiency.

Limit Depth of Cavities and Holes Keep the depth of cavities and grooves to no more than three to four times the diameter of the tool used for internal cuts. This rule helps avoid deep machining that can complicate the process and increase costs. For holes, whether blind or through, maintain a maximum depth of four times the diameter. Design holes with standard sizes to utilize standard drills for quick, precise machining. Non-standard hole sizes require end mills, which are more costly.

Design Thicker Walls Avoid designing parts with thin walls due to the increased risk of vibration, which can compromise machining quality. The minimum wall thickness for metal parts should range from 0.5 mm to 0.8 mm, and for plastic parts from 1.0 mm to 1.5 mm. Increase the thickness for walls that need to support loads or are part of taller structures to ensure stability during machining.

Opt for Simpler Text Markings While marking parts with text such as part numbers or logos adds a custom touch, it can be time-consuming. Consider alternatives like electrochemical etching or laser marking for efficiency. If machining text is necessary, opt for recessed text over raised text, keep the design simple, and limit the font depth to no more than 0.3 mm.

Adhere to Standard Thread Specifications Use standard thread sizes to simplify manufacturing and ensure compatibility. Keep the thread length to no more than three times the nominal diameter of the hole. For blind holes, include an extra half-diameter of space at the bottom to facilitate easier tapping. Consider using threaded inserts or brass nuts in materials like aluminum or plastic to enhance the durability and reparability of the threads.

CNC Machining Service

Choose AS Prototypes for precision, reliability, and rapid turnaround in all your CNC machining needs. Whether you’re developing prototypes or gearing up for full-scale production, we’re equipped to deliver superior results that meet your specifications and exceed your expectations.

CNC Machining FAQs

As experts in delivering precision-engineered parts for product developers, our CNC machining services are designed to meet the needs of functional testing and end-use applications. Explore our frequently asked questions to learn more about our capabilities and offerings.

What types of CNC machining services do you provide?

We specialize in a variety of CNC machining services including milling, turning, drilling, threading, tapping, electrical discharge machining (EDM) and wire EDM, as well as custom surface finishes. Our services extend from prototype machining to low-volume or one-off production runs, and we also offer modification of existing parts, material sourcing, and limited material warehousing with parts dispatching. Whether you need a single piece or up to 10,000 pieces, we ensure a quick turnaround with delivery times as fast as three days.

What are your capabilities in CNC machining?

Our facility spans 10,000 square feet and is equipped with advanced CNC machinery, operated by over 60 skilled technicians. We operate 24/7 and can handle more than 300 machining projects monthly, delivering over 20,000 machined parts from our CNC centers.

How much does a CNC machined part typically cost?

Costs vary based on the complexity and quantity of parts. For instance, parts produced on CNC lathes are generally 15% cheaper than those made with standard 3-axis CNC milling. However, 5-axis machining tends to be more expensive, with continuous 5-axis CNC milling costing about 20% more than 3+2 milling and roughly double that of standard 3-axis milling. To minimize costs, we recommend larger production runs which distribute the setup costs more efficiently.

What are the size limitations of your CNC machines?

- 3-axis (milling): Maximum dimensions of 1000×500×380 mm.

- 5-axis (milling): Maximum dimensions of 450×450×400 mm, with a worktable diameter of Φ400 mm.

What type of surface finish can I expect from CNC machining?

The standard surface finish from CNC machining is known as “as-machined” or “deburr,” which may include slight visible tool marks. The typical machined surface roughness (Ra) is between 1.6 and 3.2 μm. For finer finishes, we can achieve roughness levels of 0.8-1.6 μm or even 0.2-0.8 μm, though these higher specifications increase both the operational time and cost.