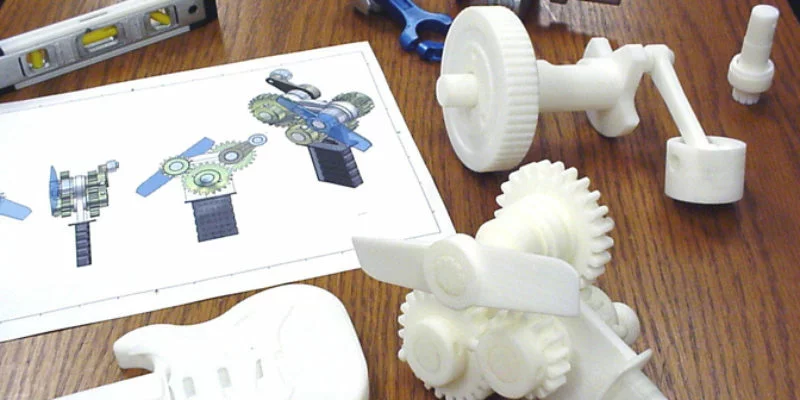

With the advancement of technology, 3D printing has transitioned from a mere concept to a tangible reality. In an industry saturated with competition, manufacturers are now focused not only on producing goods but also on employing innovative methods to increase production efficiency. To achieve this, many manufacturers are turning to various rapid prototyping techniques. These cutting-edge methods not only save time but are also cost-effective. One prominent rapid prototyping technique in use today is 3D printing, which includes SLA (Stereolithography) and SLS (Selective Laser Sintering) prototyping. Beyond just saving time and reducing costs, 3D printing excels at creating highly functional prototypes directly from 3D CAD models.

History Of 3D Printing

The concept of 3D printing dates back to 1981 when the Nagoya Municipal Industrial Research Institute used photo-hardening thermoset polymers to create three-dimensional models, utilizing a mask pattern to control UV exposure areas. However, its application was limited at the time due to material constraints and the lack of advanced 3D modeling software. By 2000, China had begun importing commercial rapid prototyping equipment, with industrial 3D printing being one of the primary applications. The term “3D printing” gained widespread recognition in the industrial world in 2013, when NASA employees Samantha Snabes and Matthew Fiedler introduced Gigabot, the first affordable 3D printer prototype.

3D Printing: A Leading Trend In Rapid Prototyping

From reducing costs to increasing efficiency through innovation, many are excited about the future impact of 3D printing on manufacturing. However, the truth is that 3D printing has already significantly influenced both the industry and domestic consumers.

Domestic 3D printers are often used as R&D tools and for designing 3D models in various industries. However, it’s incorrect to assume that 3D printers are solely for industrial use. They are becoming increasingly popular among civilian users due to their wide range of applications. This is largely because the materials used in 3D printing are becoming cheaper and more readily available over time. Additionally, 3D printers occupy much less space compared to traditional subtractive manufacturing methods such as CNC milling, lathes, and precision grinding.

The availability of advanced modeling software is also driving the development of 3D printing technology. Typically, models are saved in STL format, a CAD file format for rapid prototyping that stores data based on the triangulation of CAD models. However, this format often results in errors due to the large number of lattice structures it uses. Newer software now stores files in the Additive Manufacturing File Format (AMF), which produces fewer errors. Moreover, these software programs feature user-friendly interfaces, making it easier for both domestic and industrial users to create 3D models.

A recent study projected that 6.7 million 3D printers would be shipped worldwide by 2020, a figure 14 times higher than in 2016. As new technologies continue to enhance the capabilities of 3D printers, this technology will undoubtedly propel the manufacturing industry to even greater heights.

Figure 1: Global unit shipments of 3D printers from 2015-2020

3D Printing Technology

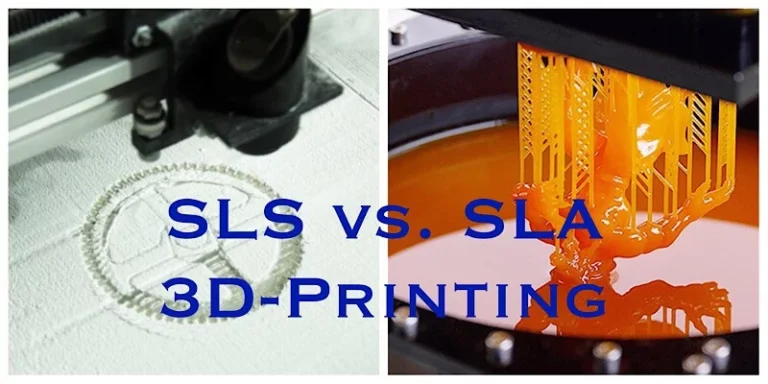

When it comes to 3D printing technology, there are two most commonly used technologies: SLA Rapid Prototyping & SLS rapid prototyping.

1. SLA Rapid Prototyping

SLA rapid prototyping, also known as Stereolithography, is a type of 3D printing technology used to create various prototypes, models, and patterns in a layer-by-layer fashion through the process of photopolymerization. Photopolymerization involves the linking of molecules to form polymers under the action of light. Essentially, the resin (the material used to create the prototype) is solidified using light and ultraviolet rays. Through this method, SLA rapid prototyping builds the desired prototype layer by layer.

Figure 2: A figure showing the processes of SLA rapid prototyping

UV radiation is used to build a pre-programmed shape within a vat of photopolymer resin. Since photopolymers are sensitive to UV radiation, the resin solidifies upon exposure, forming a single layer of the desired prototype. This process is repeated, layer by layer, until the entire prototype is completed.

SLA prototyped products boast the highest resolution and surface finish among all 3D rapid prototyping techniques. However, the true versatility of SLA lies in the variety of resins used. With technological advancements, material engineers have developed different resins for SLA prototyping that possess properties comparable to standard engineering thermoplastic materials.

Uses

SLA rapid prototyping is widely used in different industries for the development of products since its inception.

· Medical Modeling

SLA rapid prototyped products have been utilized in the medical field since the technology’s inception. They are employed to create anatomical 3D models of various regions of a patient’s body based on data obtained from computer scans. These models aid in diagnosis and treatment, providing surgeons with valuable assistance during surgeries and helping prosthetists manufacture custom-fitting implants.

Figure 3: A model produced by SLA rapid prototyping

· Prototyping

SLA rapid prototyping is also employed to create prototypes of both even and irregularly shaped materials at a relatively lower cost. Prototypes produced using the SLA method can be machined and serve as patterns for various metal casting operations.

2. SLS Rapid Prototyping

Selective Laser Sintering (SLS), commonly referred to as SLS rapid prototyping, utilizes a laser to solidify powdered material, typically nylon. Nylon is an engineering thermoplastic known for its impressive mechanical properties, lightweight nature, and stability. In this process, a laser is automatically directed at the powdered material, causing it to solidify and form the desired structure.

SLS rapid prototyping differs from Selective Laser Melting (SLM). In SLM, the material is completely melted, whereas in SLS, the material is sintered, meaning it is heated just enough to fuse the particles together without fully melting them.

Figure 4: A figure showing the processes of SLS rapid prototyping

SLS rapid prototyping, like SLA rapid prototyping, utilizes computer-aided designs (CAD) to develop the required prototype using sintered powder. It employs a high-power laser, most commonly a carbon dioxide laser, to fuse small particles of powdered material to form the desired prototype. The laser scans the cross-sections generated by the CAD model, selectively fusing the sintered materials into the shape of the required prototype. Once a cross-section is scanned, the powder bed is lowered, and a new layer of material is applied on top. This process is repeated until the desired product is fully formed.

The use of nylon in SLS rapid prototyping makes it particularly useful for creating prototypes with high mechanical strength, as well as those that are resistant to impact, light, and water. The lower production costs and high productivity associated with this technique have made it quite popular among industries for rapid prototyping.

Uses

SLS rapid prototyping is widely used in different industries for the development of products since its inception

· Aerospace Industry

SLS rapid prototyping is particularly popular in industries where high-quality parts are required in smaller quantities. One notable example is the aerospace industry, where prototypes for aircraft are essential. Since aircraft and other aerospace vehicles are produced in limited numbers and are designed to remain in service for decades, SLS rapid prototyping is ideal for producing the high-quality parts needed in this sector.

Figure 5: A compartment panel produced by Airbus by using SLS rapid prototyping

· Prototyping of Complex Geometries

SLS rapid prototyping is widely used in industries to produce complex geometries based on CAD models. This is because SLS can create prototypes from a variety of materials, fusing them under the action of a laser. Additionally, the process does not require support structures, which further enhances its popularity among industries that produce high-quality parts.

Figure 6: A propeller designed by SLS rapid prototyping

Comparison Between SLA And SLS

- Raw Material Used

- SLS: The raw materials used include Nylon powder, polycarbonate powder, and vinyl chloride powder, all of which offer high performance.

- SLA: The raw material is a liquid polymer, which does not match the quality of thermoplastic materials.

- Material Shrinkage

- SLS: Material shrinkage ranges from 2-4%.

- SLA: Material shrinkage is less than 0.4%, allowing for more detailed parts to be produced.

- Build Size

- SLS: Can produce prototypes up to 345 x 345 x 420 mm.

- SLA: Can produce prototypes up to 800 x 800 x 550 mm.

- Surface Finish

- SLS: The surface finish is rough and somewhat loose.

- SLA: The surface finish is relatively smooth.

- Strength

- SLS: The produced parts have high strength due to the raw materials used.

- SLA: The produced parts have relatively low strength.

- Machining Operation

- SLS: The produced prototypes are easy to machine, including milling, lathe, drilling, etc.

- SLA: Due to the low strength of the prototypes, machining is difficult and requires great care.

- Resistance to Wear and Tear

- SLS: Resistance to wear and tear is similar to that of thermoplastic materials.

- SLA: Poor resistance to environmental conditions, although the use of epoxy resins can considerably improve resistance.

Figure 7: A Model produced by SLS rapid prototyping

Benefits: 3D Printing Using SLA And SLS

- Cost Effectiveness

- One of the primary benefits of 3D printing is its cost-effectiveness. The prototypes produced through this process often require no modifications, saving money. Additionally, the ability to mass-produce products with 3D printing also results in significant cost savings.

- Speed

- 3D printing allows industrialists to produce a greater number of products at a higher speed, consuming much less time compared to conventional industrial processes. The only requirement is a CAD model, which the printer uses to develop the product quickly. The prototypes produced are of high quality and strength, making this technique popular among both industries and civilians worldwide.

- Reduction of Storage Space

- 3D printers occupy much less space compared to conventional mass production machinery. Additionally, the tools for traditional machines are often heavy and expensive, whereas a compact 3D printer consumes much less space and is more economical.

- Mitigation of Risk

- 3D printing allows for the verification of a design before the production of an expensive prototype in the CAD model. This enables corrections to be made to the CAD model before final production. Moreover, producing test molds with 3D printing is far cheaper than altering an already produced mold.

- Feedback

- Prototypes created through 3D printing can be used to test the market potential of a product before actual production. The response from buyers can help predict the future prospects of the product and assist in deciding the quantity to be mass-produced for market supply.

- Personalization

- Unlike standard machining operations used for mass production, where all parts come off the machine or mold with the same design (and defects, if any), 3D printing offers room for customization and personalization of products as required by customers or market demands.

Concluding Remarks

SLA (Stereolithography) and SLS (Selective Laser Sintering) prototyping have revolutionized the technological landscape by making the production of functional prototypes significantly easier. These techniques allow for the creation of prototypes tailored to specific requirements. SLA excels in providing superior surface finishes, while SLS is ideal for producing high-strength products. Both methods are leading rapid prototyping technologies and are suitable for mass production with minimal errors.