The automotive industry is crucial to our daily commutes, whether for work or leisure. A key component of this industry is CNC technology. Without CNC machining, the design and appearance of the cars and vehicles we see today would be vastly different.

CNC Machining Leads the Way in the Automotive Industry

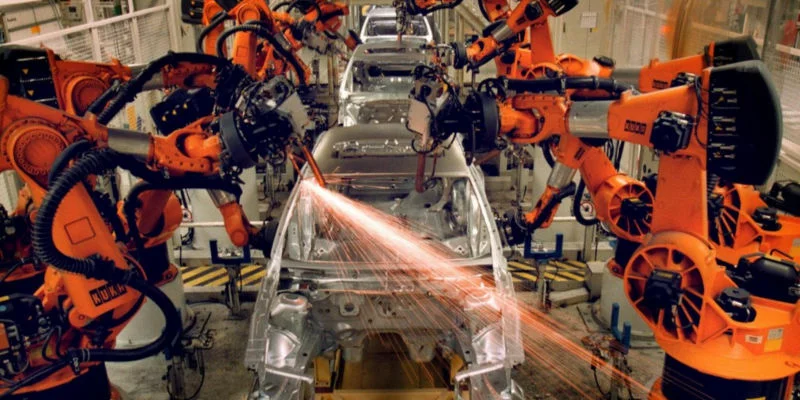

CNC machining plays an integral role in the automotive industry, from die-casting various components to crafting intricate single body frames. CNC machine tools are responsible for manufacturing a wide array of automotive parts, including carburetor housings, suspension components, bearing caps, and engine housings. State-of-the-art CNC machines and tools are employed in these processes, ensuring precision and efficiency.

PMMA/Acrylic precision machining is particularly noteworthy for producing headlights and other lighting components on automobiles, showcasing the marvels of CNC technology. Today, CNC has become the standard and primary method for manufacturing numerous industrial-grade automotive parts.

CNC (Computerized Numerical Control) significantly contributes to rapid manufacturing and production, as well as precise material handling. CNC’s digital processing code offers numerous advantages over traditional machine tools, which cannot compete with CNC’s capabilities. CNC machine tools boast the following characteristics:

- High Precision: Ensures accurate production of complex parts.

- Excellent Product Consistency: Maintains uniformity across large production runs.

- Multi-Axis Linkage: Allows for intricate and complex machining tasks.

- High Degree of Automation: Reduces manual intervention and increases efficiency.

- Low Labor Intensity: Minimizes the physical demands on workers.

- Short Mechanical Transmission Chain: Simplifies the structure and enhances production efficiency.

These characteristics are highly favored in the batch production of various automotive components, enabling effective and rapid manufacturing processes. The superior precision, consistency, and efficiency of CNC machining have significantly enhanced the quality and reliability of modern vehicles compared to those produced before the advent of CNC technology. This technological advancement has made our cars more dependable and advanced than ever before.

1. Power

It’s truly an engineering marvel how much horsepower modern car manufacturers can now pack into a small engine. Around 25 years ago, a 2-liter engine could deliver a maximum of 100 horsepower. Today, engines of the same size can deliver an astonishing 200 horsepower. What accounts for this difference? The introduction of CNC technology is key, allowing engines to be built with significantly higher precision and efficiency. CNC machining enables manufacturers to design engines with tighter tolerances, packing more power into a relatively compact space.

*Complex geometries inside a car engine – only possible due to CNC

2.Reliability

There was a time when starting your engine on a cold morning or after several days of inactivity was a game of chance and luck. In the days before CNC technology, automobiles were often unreliable. Today, thanks to high precision manufacturing enabled by CNC machining, modern vehicles are more reliable and dependable than ever before.

3.Time-efficient and rapid production

With CNC technology’s ability to produce small parts in extreme detail and perform repetitive manufacturing effortlessly, automobiles have become more efficient and readily available in the market. This substantial implementation of CNC in the manufacturing process has enabled companies to meet the massive spike in car demand from customers, ensuring a steady supply of high-quality vehicles.

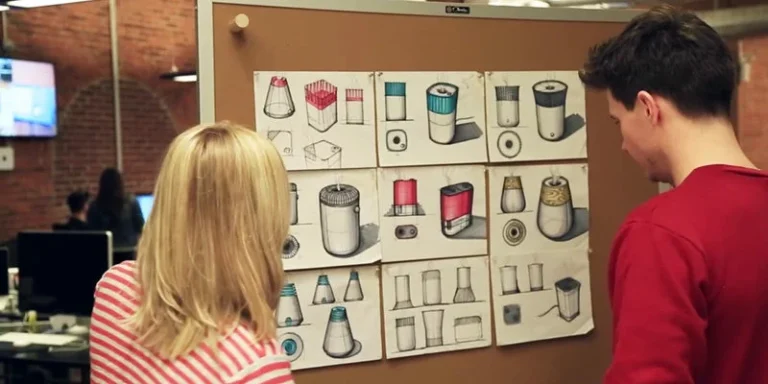

*Prototype clay CNC manufacturing for a car model

5-Axis CNC Machining in the Automotive Industry

With the automotive industry’s demand for precise and complex parts, multi-axis manufacturing has become indispensable. Specifically, 5-axis CNC machining is crucial as it eliminates the need for multiple machine setups. This technology allows for the production of intricate geometries on a single machine by utilizing different axes. In 5-axis CNC automotive machining, the machine can stay tangent to the workpiece, enabling rapid multi-axis cutting. While the initial setup cost of such a system is higher compared to a single-axis CNC setup, it offers significant long-term benefits, including shorter turnaround times and highly precise cuts, making it a worthwhile investment.

1.Automotive parts and CNC

CNC is now a widely adopted method in automotive manufacturing, playing a crucial role in producing several essential components of various automobiles. Some of these components include:

2. Gearbox

A gearbox is a vital transmission mechanism in an automobile, ensuring that the engine’s power is efficiently and effectively transferred to the wheels. Today, all the gears and shafts within a gearbox are precisely manufactured using CNC machine tools. Various CNC techniques, such as milling, turning, and surface grinding, ensure that the shafts and gears inside the gearbox are reliable, precise, and capable of transmitting power in the most efficient manner possible.

3.Drive axle

The drive axle is another critical transmission mechanism that transfers power from the gearbox and engine to the wheels. The two primary hypoid gears in the central axle of the drive axle must be machined with CNC technology to achieve the highest level of precision. Additionally, CNC machines are used to machine the bevel gears in the differential, ensuring a smooth ride and stability.

4.Headlights and backlights

With many leading car manufacturers introducing intricate headlight and backlight designs, no other production method matches the precision and efficiency of CNC machining. CNC technology enables the creation of complex shapes from a solid block without layer lines, allowing manufacturers to produce head and tail lights with clear and smooth surfaces for excellent light transmission.

5.Verdict

CNC automotive manufacturing has revolutionized the way we perceive cars and their production process. In the past, only a limited number of vehicles could be produced for each model, but with the advent of CNC technology, car manufacturers can now produce the same model in virtually unlimited quantities. The repetitive manufacturing capabilities of CNC machines have not only transformed the automotive industry but also impacted global trade by enabling the mass production of goods with exceptional precision. The level of perfection achieved through CNC manufacturing in the automotive sector is unparalleled, surpassing any other manufacturing method available today.

*CNC machined rim for a car

AS Prototypes incorporates premium 5-Axis CNC manufacturing techniques with state-of-the-art CAM and CAD software. At AS Prototypes, we offer prompt automotive prototyping solutions to ensure that your automotive-related products and prototypes are manufactured with the utmost quality and precision in a timely manner.