In the past, manufacturing efficiency was primarily judged by product quality and cost. Today, sustainability has emerged as a crucial factor. Modern manufacturing not only aims to produce high-quality products but also strives to minimize environmental impact. This is particularly important as manufacturing processes often involve hazardous materials and pollution. Rapid prototyping companies, despite their smaller scale, are joining the sustainability movement. But how can they achieve green manufacturing?

Understanding Green Manufacturing in Rapid Prototyping

Green Manufacturing goes beyond reducing carbon emissions and avoiding harmful chemicals. It encompasses a wide range of practices aimed at sustainability. For instance, using recyclable metals and plastics can significantly reduce production waste. Other strategies include switching to paperless documentation, utilizing leftover heat from processes, and adopting power-saving modes in equipment. There are numerous ways to embrace green practices.

The Role of Rapid Prototyping in Sustainable Manufacturing

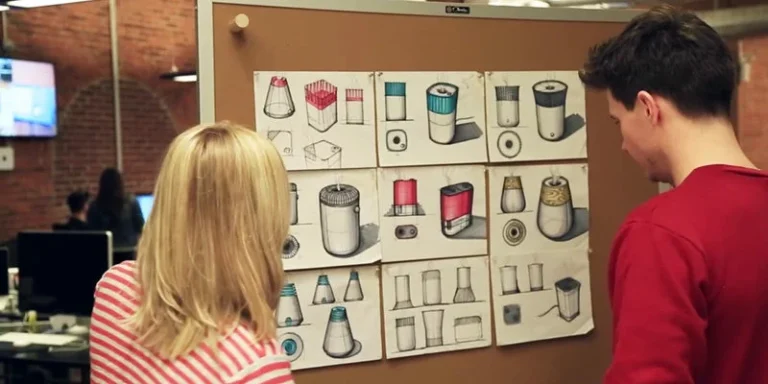

Rapid prototyping plays a vital role in sustainable manufacturing by saving time and materials during product development. By creating prototype parts instead of full-scale batches, companies significantly reduce waste from machining or molding processes.

Green Approaches in Rapid Prototyping Technologies

Three technologies dominate rapid prototyping in China: 3D printing, CNC rapid machining, and silicone casting. Each offers opportunities for sustainability:

Green 3D Printing

3D printing revolutionizes rapid prototyping by reducing steps, thereby saving electricity, paper, and materials. It generates minimal waste compared to CNC machining, which discards 60-70% of material. However, 3D printing’s sustainability challenges include high electricity consumption and limited recycling options for materials like ABS. Solutions include reducing energy use or incorporating sustainable power sources like solar panels.

Green CNC Machining

CNC machining generates significant waste, which can be mitigated by minimizing machining in prototype design. Lubricants used in machining are often harmful, prompting the development of minimum quantity lubrication techniques that utilize compressed air and water instead of oil and chemicals. AS Prototypes offers sustainable CNC prototyping and rapid tooling solutions at competitive prices.

Green Silicone Casting

Silicone casting uses less electricity but poses challenges with non-biodegradable silicone molds. Partnering with recycling companies or collaborating with other firms can address this issue. Group efforts can make silicone recycling financially viable and environmentally friendly.

Conclusion

Sustainability in rapid prototyping extends beyond manufacturing. Companies can adopt greener practices without delving into complex recycling processes. Implementing product lifecycle management software can reduce paper use, while LED lighting and waste sorting can further minimize environmental impact. There are countless ways to contribute to environmental preservation, and every effort counts.