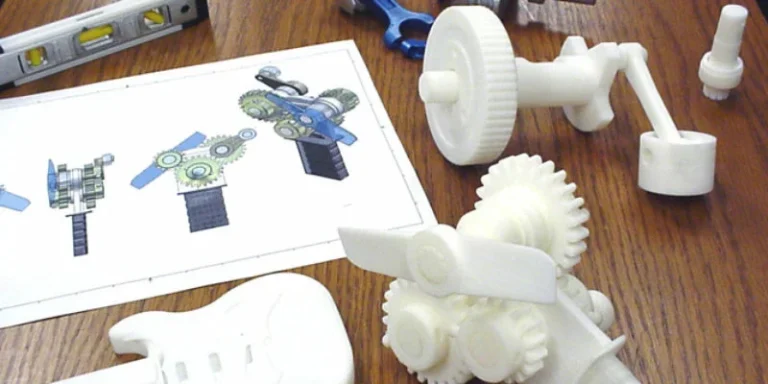

The world of manufacturing is undergoing a remarkable transformation, thanks to the rapid advancements in 3D printing technology. With its speed, versatility, and cost-effectiveness, 3D printing is gaining traction across diverse sectors such as aerospace, automotive, aviation, medical device manufacturing, and construction. In this article, we will explore how additive manufacturing is currently shaping these industries and discuss its future role in revolutionizing prototyping and manufacturing workflows.

Construction: Building the Future Engineering, architecture, and construction firms are embracing the potential of 3D printing technology on a larger scale. By utilizing 3D printing prototyping, these industries can significantly reduce waste, save time, and minimize costs. The construction sector is already witnessing the creation of inhabitable structures and model properties through 3D printing. In the future, this technology may even pave the way for the development of inexpensive and safe shelters and temporary structures.

Automotive: Driving Innovation The automotive industry continues to reap the benefits of 3D printing, particularly with advanced additive manufacturing technologies like DMLS (direct metal laser sintering) and Projet MJP. Collaborations between companies like Volkswagen and HP are enabling the creation of high-quality metal parts without the need for expensive tooling. Furthermore, giants like E.ON and Siemens have utilized 3D printing to manufacture a gas turbine burner that can operate for an impressive 8,000 hours without any downtime.

Fashion: Redefining Style 3D printing prototyping is not limited to high-end industrial applications. Even fashion designers are exploring its potential to save time and effort in creating custom accessories and cutting-edge clothing. This technology offers designers the freedom to bring their imaginative concepts to life with precision and efficiency.

Healthcare: Innovations for Well-being In the healthcare industry, 3D printing is revolutionizing the way medical device designers and manufacturers operate. By utilizing additive manufacturing, these professionals can bring their designs to life and test them in the real world. Even as prototypes, these products can be built with biocompatible materials to ensure performance and safety. Additive manufacturing also enables faster time-to-market for medical devices, and in the future, it may even enhance implant manufacturing processes.

Unlock the Future of Manufacturing with AS Prototypes If you are considering 3D printing prototyping for your upcoming projects, partner with AS Prototypes for quick and cost-effective services. As a leading provider in the industry, we are dedicated to delivering high-quality results that add value to your manufacturing process. Contact us today at info@asprototypes.com to discuss your project and benefit from our expertise. Experience a brighter future in manufacturing with AS Prototypes.