Introduction

With the rapid advancement of the global automotive industry, the time required to develop industrial prototypes for headlamps has significantly decreased. This reduction in time is essential for keeping pace with the demand for new car models in the market. Traditional design and manufacturing methods struggle to meet this demand, making it crucial to find solutions that reduce production time and the mold manufacturing cycle.

Rapid Prototyping offers an effective way to shorten the development cycle and reduce production costs, allowing for better synchronization between vehicle production and headlamp manufacturing. Complex or time-consuming components that are challenging for traditional methods can be efficiently produced using rapid prototyping.

Why are Headlamps Essential?

Car headlamps, often referred to as headlights, are not only important for a vehicle’s aesthetics but also play a critical role in ensuring safe navigation under low visibility conditions, whether due to time of day or environmental factors. To ensure headlamp functionality and safety, rigorous testing on industrial prototypes is necessary before mass production. A fully functional headlamp must include components like lenses, bezels, reflectors, and housing, and provide visibility of at least 100 meters.

Materials Used in Automotive Headlamps

In the automotive industry, plastics have become the preferred material over expensive non-ferrous metals and alloy steel. The use of plastics in headlamps not only reduces weight but also offers convenience to manufacturers and customers. Headlamps with PC (Polycarbonate) and PMMA lenses are more costly than those with glass, but they provide superior performance and durability. These plastics are more scratch-resistant, durable, and lighter than traditional glass.

Structural parts, such as the housing, are often made from ABS, PEI, and PCHT. These materials are strong, long-lasting, and lightweight, making them ideal for fast and easy production compared to other industrial materials. Reflectors in headlamps are typically made from soft steel like P-20 and aluminum such as 7075 T-6, which increase processing speed and reduce polishing time compared to hard steel.

Headlamp Prototype Manufacturing

Modern rapid prototyping techniques, including CNC machining and 3D printing, are now essential in headlamp prototype manufacturing. Based on AS Prototypes’ extensive experience, the following are key technical applications for different stages of headlamp prototyping:

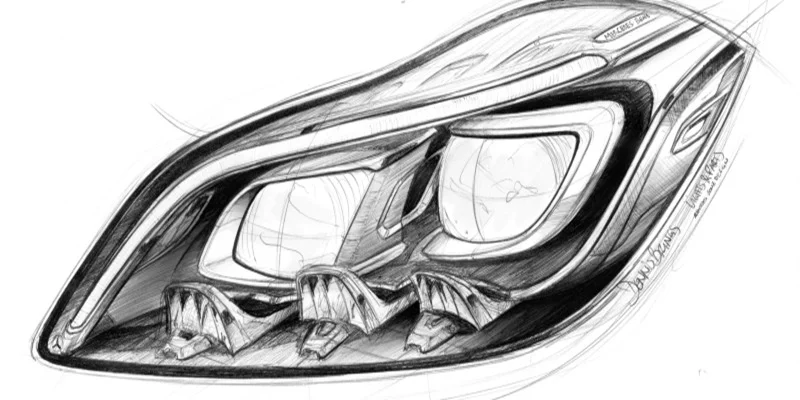

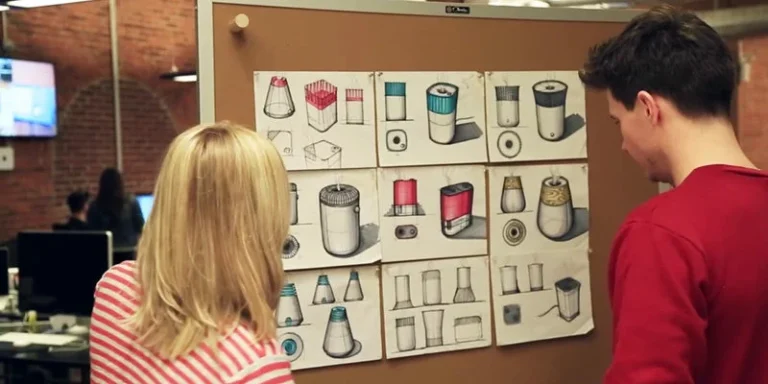

Concept Creation

Successful product design and engineering start with good concept creation and prototyping. Initially, concepts are sketched by hand to visualize ideas. Industrial-grade CAD software like Autodesk Inventor and CATIA are used in this stage. It is crucial that prototypes incorporate all the functionalities of the final product, not just aesthetic aspects.

Engineering Stage

CNC machining is often the preferred method for industrial prototypes due to its high precision and quick turnovers, typically within 1-2 weeks. For high-precision components like bezels and lenses, 5-axis CNC is used. For less precision-dependent parts, such as housings, rapid prototyping techniques like Stereolithography (SLA) are employed.

SLA for a Headlamp

Once the concept is finalized, manufacturing begins. Given the complexity and number of small parts in automotive headlamps, a single 5-axis CNC machining process cannot produce the entire headlamp. Instead, individual components are manufactured separately and then assembled.

Post-Processing

After assembly, post-processing steps like polishing, bonding, deburring, and painting are conducted. Innovative product design during the initial development stages is crucial for successful prototyping and full-scale production.

Conclusion

Developing a headlamp prototype is a complex task requiring various rapid prototyping techniques and materials. To ensure that all product design and engineering needs are met, partnering with a reliable manufacturer is essential. At AS Prototypes, we specialize in automotive headlamp manufacturing and prototyping, and we invite you to bring your ideas to life with our expertise.