Before delving into the topic, it’s essential to understand PMMA and injection molding. PMMA, short for poly-methyl methacrylate, is commonly known as acrylic. It is also referred to by other names such as Plexiglass, Crylux, Acrylite, and Lucite. The demand for acrylic glass is steadily rising in the manufacturing industry due to its beneficial properties. In today’s industrial era, PMMA (Acrylic) is extensively used in various applications due to its natural transparency, clarity, and the impact resistance of certain variants. These applications include lenses, acrylic nails, paint, security barriers, medical devices, LCD screens, furniture, windows, tanks, and exhibit enclosures.

Why PMMA or Acrylic is Ideal for Injection Molding

PMMA, or acrylic, is a thermoplastic known for its high transparency, flexibility, chemical resistance, weather resistance, and lightweight nature. It is preferred over polycarbonate (PC) due to its ease of processing, lower cost, and flexibility. PMMA is widely used in rapid manufacturing industries to create high-quality prototypes. As a thermoplastic, PMMA can be liquefied at its melting point and reshaped upon cooling, making it ideal for injection molding.

Why PMMA or Acrylic is Widely Used

Acrylic serves as a perfect glass substitute due to its moderate properties and low cost, making it a popular prototyping material across various manufacturing industries. It is also extensively used by students in universities for projects and prototypes.

Applications of PMMA Prototypes

PMMA prototypes are in high demand across industries seeking a stronger and more affordable alternative to expensive and brittle glass. PMMA is an excellent glass substitute, used in security barriers, LCD screens, windows, tanks, medical devices, and lenses. With many industries opting for PMMA, there has been a significant increase in PMMA prototypes in recent years.

Glass Substitute

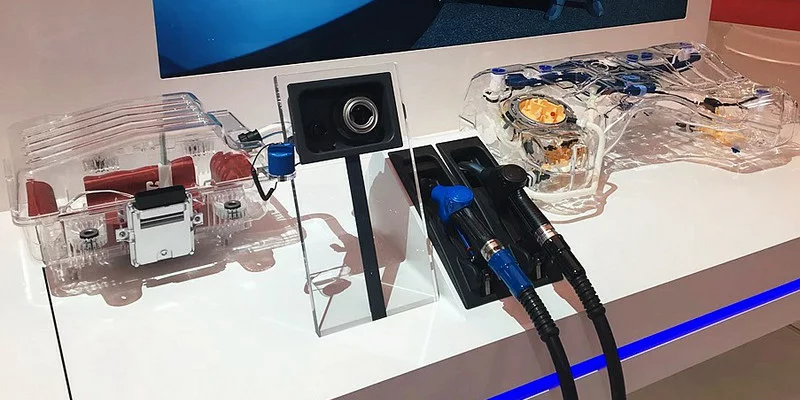

PMMA clear parts are an outstanding alternative to glass, commonly used in aquariums and as viewing ports or pressure hulls in deep-sea submersibles due to their flexibility, durability, and low cost. PMMA is also used in automotive headlight and backlight lenses, offering better protection against impacts. Many safety vehicles and buildings use PMMA instead of glass for windows due to its superior strength.

Attractive and Futuristic Appearance

PMMA is favored by automobile companies, manufacturers, and furniture showrooms for its futuristic looks and material properties, capturing people’s attention.

Medical Industry

In the medical field, PMMA prototypes and products are prevalent. Contact lenses and eyeglass lenses are often made from PMMA due to their reduced brittleness compared to glass. PMMA’s compatibility with human tissue makes it suitable for cataract treatment. It’s also used in bioprocess chromatography, tuberculosis treatment, cosmetic surgeries, and denture teeth.

Properties of Acrylic

| Properties | Values |

|---|---|

| Technical name | Poly-Methyl Methacrylate |

| Chemical name | (C5H8O2)n |

| Melting Point | 130°C |

| Specific Gravity | 1.18 |

| Shrink rate | 0.2 – 1% |

| Tensile strength | 65 MPa |

| Flexural strength | 90 MPa |

| Visible light Transmission | 92% |

| Standard Injection Mold Temperature | 130°C |

Why PMMA Material is Suitable for Prototyping

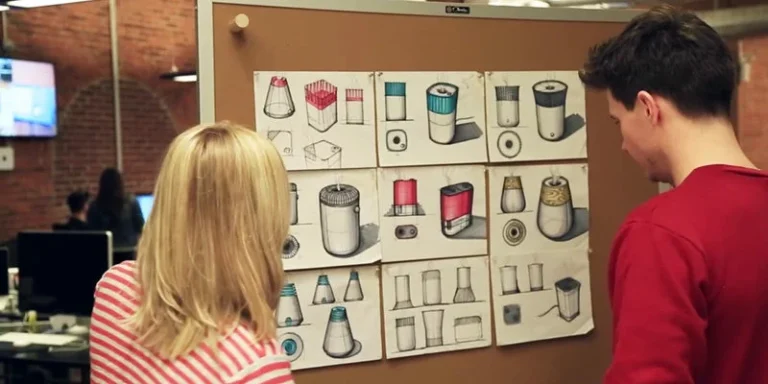

Before PMMA, prototyping was challenging and expensive, often involving metallic prototypes and polycarbonate, which poses health risks due to bisphenol-A. PMMA is now favored for creating flexible, lightweight, and scratch-resistant prototypes.

Manufacturing Techniques for PMMA Prototyping

For creating clear and fine parts, acrylic is preferred over glass, which is unsuitable for non-flat surfaces. Several rapid production techniques exist for PMMA clear parts and prototypes. At AS Prototypes, we utilize various rapid prototyping techniques to deliver cost-effective, high-quality prototypes. Besides acrylic injection molding, CNC machining is used for complex geometries that require hand polishing, allowing for intricate and precise designs.

PMMA Injection Molding

Injection molding involves liquefying the material at high temperatures, injecting it into metallic dies under pressure, and allowing it to cool. PMMA injection molding is a popular and effective method for producing high-quality plastic parts and prototypes. This process involves heating PMMA resin to its melting point, injecting it into metal dies, and cooling it rapidly to form the desired shape. Injection molding is widely used in industries like electronics, manufacturing, and automotive.

For urgent prototypes, 3D prototyping is recommended, but for functional and reliable parts, plastic injection molding is preferred. While injection molding is often seen as costly for high-volume production, it is reliable and suitable for prototyping or low-volume production.

How PMMA Injection Molding Works

The process involves several steps to fabricate a final prototype or product. The initial step is designing the part, focusing on feasibility and production without considering size. The engineering phase involves drafting and designing parts for easy production in steel or metal dies. Proper wall thickness, gate placement, and molten material flow are crucial for successful prototypes.

The next phase involves designing mold geometry, including pins for ejection and water lines for cooling. Aluminum molds are preferred for prototypes due to their heat dissipation and improved molten material flow, while steel molds are used for high production volumes. Complex molds may require the EDM process, with single or double cavity molds used as needed.

Final adjustments ensure the injection molding process works effectively from the first run.

Advantages of PMMA Injection Molding

PMMA parts can be produced through both injection molding and traditional machining, but injection molding offers several advantages:

- Reliable shape and size consistency

- Ability to create complex shapes

- Rapid production of final parts

Processing Conditions for PMMA Injection Molding

- Drying: PMMA should be dried before molding at 90°C for 2 hours.

- Melt Temperature: 245°C – 280°C

- Mold Temperature: 40°C – 80°C

- Injection Speed: Normal