5G technology is set to revolutionize the world by creating a fully connected and intelligent digital landscape. Huawei, a leader in 5G innovation, showcased its vision at the 2019 Mobile World Congress in Barcelona with the theme “The Digital Village,” highlighting the transformative potential of 5G connectivity.

Driving the 5G Revolution

The global push for 5G is well underway. Sunrise CEO Olaf Swantee announced at Huawei Day0 Forum 2019 that Switzerland is leading the charge, with plans to launch 5G services in March, covering over 150 cities. Similarly, Monaco Telecom’s CEO, Martin Peronnet, signed an MoU with Huawei to advance the “Smart Nation” initiative, aiming to transform Monaco into a 5G-enabled smart nation. In Southeast Asia, XL Axiata has partnered with Huawei to establish the region’s first 5G-ready network across Indonesia, enhancing connectivity for individuals, families, and businesses.

The Necessity of Upgrading Infrastructure for 5G

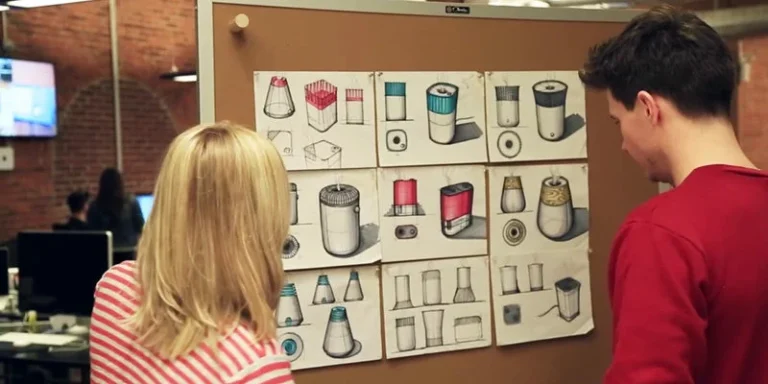

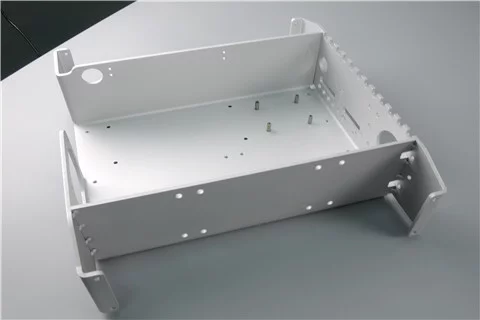

The advent of 5G, with its potential download speeds of up to 10Gbps, surpasses the capabilities of current 4G and traditional WiFi networks. Existing infrastructure cannot support the higher demands of 5G, necessitating a complete overhaul of facilities and machine rooms. This involves redesigning and testing numerous industrial components, a process that includes precision machining of metal parts such as sheet metal and aluminum covers.

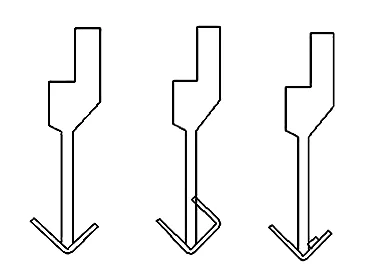

Sheet Metal Machining for 5G Infrastructure

Sheet metal fabrication is crucial for 5G infrastructure, utilizing techniques like laser cutting, bending, and wire cutting. Different bending tools accommodate various shapes and structures, ensuring precision and quality without affecting part tolerances. Properly managed, these processes prevent deformation and maintain part integrity.

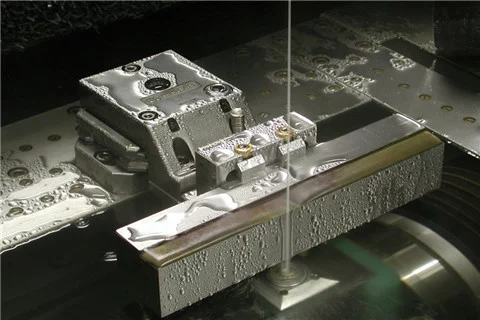

CNC Aluminum Cases for Smart Devices

CNC machining, particularly wire cutting and EDM (Electrical Discharge Machining), plays a vital role in producing precise components for 5G devices. Wire cutting allows for the creation of complex parts from conductive materials like aluminum and copper, offering a cost-effective alternative to traditional milling and turning. EDM provides extreme accuracy for delicate parts, though it requires careful management of dielectric fluid to maintain stable electrical discharges.

For metal parts, EDM is often used to machine undercuts, as metals cannot be glued as effectively as plastics. Post-EDM, surfaces may require additional processing to achieve the desired cosmetic quality, especially for parts used outdoors. Anodizing and powder coating are common treatments that enhance durability and appearance, with options for hard anodizing and outdoor-specific coatings.

The Future of 5G and Machining Technology

As 5G technology propels us into a new era of innovation, machining methods must evolve to meet the precision and quality demands of modern designs. The goal is to reach a level of automation and intelligence where design constraints during machining are minimized, paving the way for unprecedented creativity and efficiency.

5G is poised to usher in a new wave of technological advancement, offering significantly faster download and upload speeds while reducing latency. This next-generation mobile broadband will not only enhance current 4G LTE connections but also unlock new possibilities for connected devices and smart technologies.