With the advent of personal computers, numerical systems have permeated every industry, including manufacturing. Today, the benefits of CNC machining are widely recognized by manufacturers across various sectors for their fabrication and manufacturing needs.

CNC systems have become integral to modern machining technologies. “CNC” stands for Computer Numerical Control, which means that machine tool mechanisms are connected to and controlled by a specialized digital system. This automation can effectively replace manual operations. At AS Prototypes, CNC prototyping techniques have significantly advanced due to the revolutionary innovations in CNC machinery. We have developed a deep understanding of the differences between traditional and CNC machining, as outlined below:

The Principles Of Conventional And CNC Machining

The CNC system comprises both hardware and software components. The hardware handles the computational tasks, while the software allows the operator to monitor machine tool parameters and create CNC programs.

CNC programs are essentially lists of instructions detailing how the machine tool should operate to process a specific part. The CNC hardware reads these instructions line by line, directing the machine tool to perform the required actions accordingly.

In contrast, conventional machining relies on the operator to directly control all movements of the machine tool. The operator decides when and how to move the tool, including the feed rate, when to stop, and the precise location of operations. For higher precision, the operator uses gauges and specialized rulers integrated into the control levers.

The Advantages Of CNC Machining

1.Labour Safety

First and foremost, CNC machining enhances safety. The operator of a CNC machine is protected from sharp components by a specialized protective enclosure. While the operator can observe the machine tool’s operations through a glass window, there is no need to approach the mill or spindle closely. Additionally, the operator is not required to come into contact with cooling fluids. Depending on the material being machined, some of these fluids can be hazardous to human skin.

2.Labour Economy

In the era of conventional machine tools, constant attention was required from the operator, who had to manually control every movement of the tool. This meant that each worker could only operate a single machine tool at a time. However, the advent of CNC technology brought a significant change. Most parts require at least half an hour to process for each setup, but with CNC machines, the cutting is done automatically. The operator no longer needs to manually adjust the tool; instead, they only need to monitor for any errors in the program or setup.

3.Minimum Setup Error

Conventional machine tools depend heavily on the operator’s skill with measuring tools. While highly skilled operators can achieve great precision in setting up parts, such expertise is relatively rare. To address this, many CNC systems incorporate a specialized coordinate measuring probe. This probe is typically installed into the spindle like a tool and is used to touch the fixed part to determine its position. By doing so, the coordinate system’s zero points are accurately established, minimizing setup errors and enhancing overall precision.

4.Excellent Machine Tool Conditions Monitoring

With conventional machining, operators had to rely heavily on their intuition and experience to detect machining faults and determine when cutting tools were becoming blunt. This approach was inherently subjective and often led to suboptimal decisions. In contrast, modern CNC machining centers are equipped with an array of sensors that monitor various parameters such as torque, temperature, and tool life in real-time. This advanced monitoring allows operators to optimize the machining process as it happens.

For example, if the temperature becomes too high, which can lead to increased tool wear and degraded metal properties, the operator can adjust the feed rate or increase coolant pressure to mitigate the issue. Despite some misconceptions, machining remains the most prevalent fabrication method today. This process of material removal, developed since ancient times, has evolved into a highly precise and sophisticated fabrication technique. Machining is utilized across all industries to varying extents, with some sectors benefiting more significantly from its capabilities.

5.Stable Replication Accuracy

What’s more stable than a verified computer program? In CNC machining, the movement of the instrument is consistently precise, as it relies on the accuracy of step-motors. This ensures that each operation is executed with the same level of precision every time. In contrast, conventional machining relies on the operator’s skill, leading to significant variability in replication accuracy. Human error is inherently greater than the minimal errors found in a well-programmed CNC system.

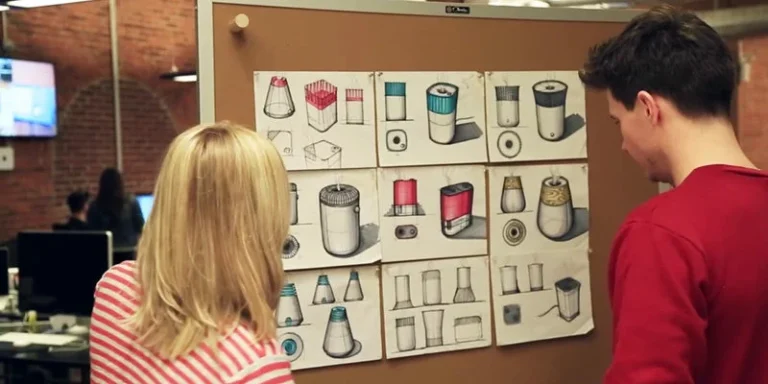

6.Fewer Test Runs

Conventional machining often requires the production of a few test parts. This is necessary for the worker to familiarize themselves with the technology and process, and it is almost certain that some errors will occur during the initial attempts. In contrast, CNC systems can avoid the need for test runs by utilizing visualization systems. These systems allow the operator to see a simulation of what will happen to the stock after all the tool passes are completed, ensuring that any potential issues can be identified and corrected before actual machining begins.

7.Complex Surfaces Are Easy To Manufacture

Manufacturing complex surfaces with high precision using conventional methods is nearly impossible due to the tremendous amount of manual labor required. In contrast, CAM (Computer-Aided Manufacturing) systems can automatically generate tool paths for any surface. This automation eliminates the need for manual effort, making it one of the most significant advantages of modern CNC machining technologies.

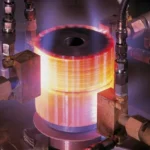

8.Higher Cutting Parameters

High-speed machining has become feasible primarily due to the sealed cutting zone. At such high speeds, chips are expelled at high velocities, accompanied by a shower of coolant fluid administered at high pressure. Manual operation becomes impractical when speeds reach 10,000 rpm or more. The high cutting speed necessitates maintaining a stable feed rate and chip width to prevent vibration, a task that is exceedingly difficult to achieve manually. The automation and precision of CNC systems make high-speed machining possible and efficient.

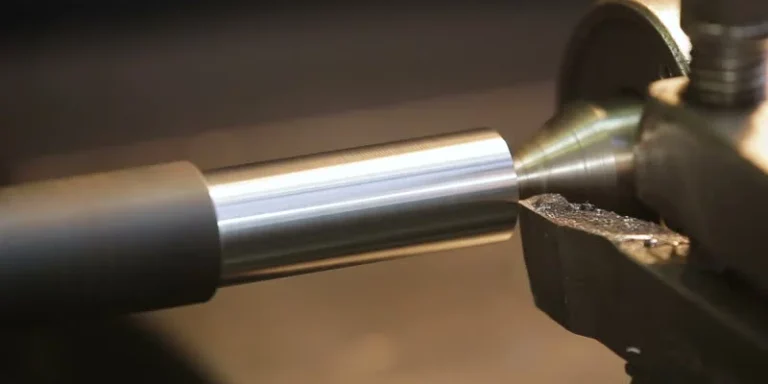

9.Higher Machine Tool Flexibility

Traditionally, specific machine tools were dedicated to distinct operations: milling machines created grooves and planes, lathes produced cylinders and tapers, and drilling machines made holes. However, CNC machining integrates all these capabilities into a single machine tool. By programming the tool’s trajectory, any movement can be replicated on any CNC machine. This flexibility means that milling centers can produce cylindrical parts, and lathes can mill grooves, significantly reducing the need for multiple setups and increasing overall efficiency.