In everyday conversation, we often use the terms “headlamp” and “headlight” interchangeably. However, to be more precise, “headlamp” refers to the actual device, while “headlight” describes the beam of light that the device produces and distributes.

Why Is The Headlamp So Important?

Why are headlamps so important? Whether it is day or night, we see an endless stream of vehicles on the road. Although only 25% of traffic occurs in the dark, according to the National Bureau of Transportation, the probability of a traffic accident during these hours is significantly higher. Therefore, headlamps are crucial for ensuring travel safety. Additionally, headlamps allow designers to track the driver’s eye movements to better understand their behavior.

As a result, headlamp performance has been continuously optimized in the automotive field. This optimization extends beyond just cars, encompassing small generators for bicycles, trains, and airplanes, all of which require mechanical integration for proper function. A high-quality front lighting system necessitates the cooperation of various components to provide the end customer with an enhanced visual experience and perceived quality.

Prototype headlamps are primarily composed of several key parts: the lens, bezel, light guide, reflectors, and housing. Let’s take a closer look at some of these automotive components.

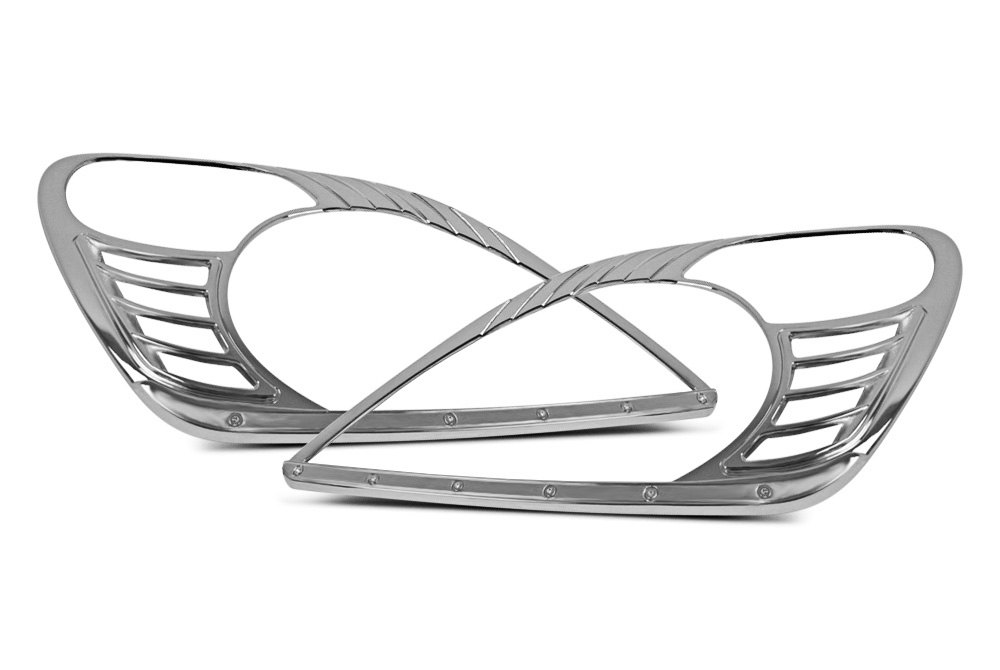

Headlamp Bezel

The bezel is positioned on the front upper side of the filament within the vacuum wick. Its primary function is to block direct light from the filament when it is illuminated. If this upward light from the headlamp is not blocked, it can cause severe glare for oncoming drivers and create a light curtain in front of the car in rainy or foggy conditions, reducing visibility for the driver.

Prototype bezels are typically made from materials such as PMMA (Polymethyl Methacrylate) or ABS (Acrylonitrile Butadiene Styrene). These materials are chosen for their properties, which include heat resistance, the ability to be metalized, and high surface quality.

Headlamp Reflector

The light source of the headlight system comes from the bulb, but it also requires the cooperation of the reflector.

The reflector is an internal component of the headlamp and is part of the secondary optics. Its function is to perform secondary light distribution, concentrating the light from the automobile LED headlight. Reflectors are crucial for the light effect of the luminaire. Without them, the luminaire market would regress to its earlier stages. The reflector effectively amplifies the illumination output from the bulb using the principle of a concave mirror. Additionally, it has an anti-glare function to help the driver stay focused.

There are three common production technologies for reflectors:

- Plastic Reflector:

- Advantages: Low cost, easy one-step release.

- Disadvantages: Poor optics and temperature resistance.

- Usage: Suitable for lamps with low temperature requirements.

- Metal Reflector:

- Advantages: Moderate cost, good temperature resistance.

- Disadvantages: Requires stamping and polishing processes.

- Usage: Often used in flashlights and portable lamps.

- Glass Reflector:

- Advantages: High optical precision, temperature resistance.

- Disadvantages: High cost, fragile, heavy.

- Usage: Used in high-quality, stationary products such as film projectors, searchlights, and train headlights.

Combining the advantages and disadvantages of these options, we typically use ABS prototype reflectors or chrome aluminum prototype reflectors.

Prototype Chrome Aluminum Reflectors: Aluminum material has good ductility, is easy to process, and has a high heat distortion temperature, making it suitable for electroplating and coating treatments. After vacuum aluminum plating, a thin and stable oxide layer forms on the surface, providing high corrosion resistance. Closed vacuum wick mirrors are mostly paraboloids formed by parabolic rotation. During production, the vacuum coating process evaporates the aluminum onto the inner surface, resulting in very high brightness. The brightness of the reflected light is more than 6000 times higher than the brightness of the filament itself.

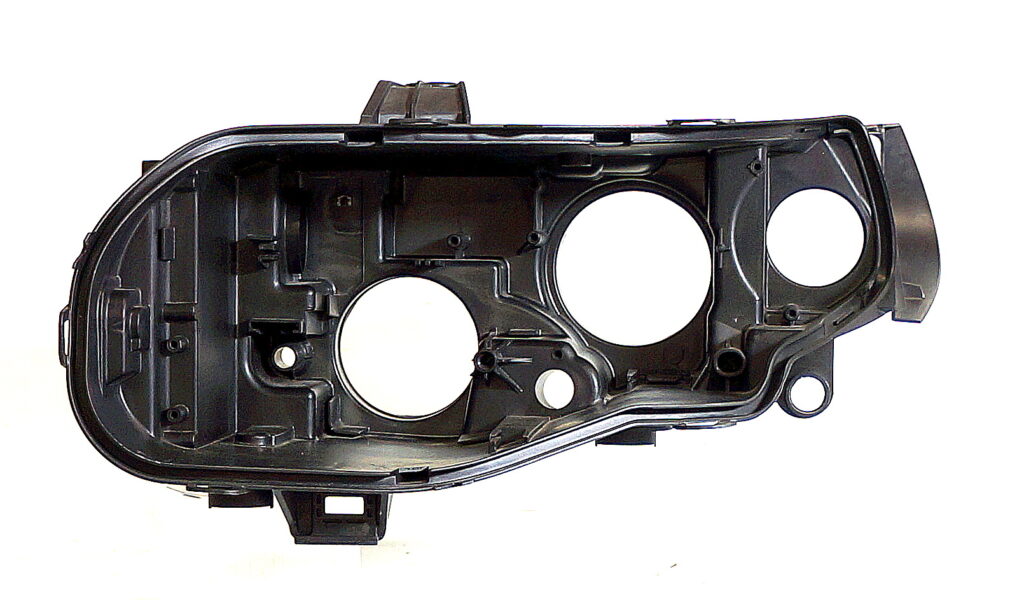

Some headlamps rely solely on the special structure of the reflectors, with complex shapes and high processing precision, to meet light distribution requirements. However, the design, calculation, mold precision, and processing technology of these reflectors are challenging. The picture below shows a prototype of the reflector made by the AS Prototypes team.

The inner shape of the reflector comprises various paraboloids. The accuracy of each profile significantly influences the light type, presenting the biggest processing challenge. Nevertheless, the AS Prototypes team has the expertise to handle such workpieces exceptionally well. The overall appearance is glossy, achieving a Class A surface effect and greatly improving reflectivity.

Headlamp Housing

The headlamp housing has the essential function of supporting the headlight assembly and securing the vehicle’s headlights in place to maintain their proper position on the vehicle. Different vehicle manufacturers and models have various front-end assembly configurations, so the location of the mounted headlight housing will depend on your vehicle’s design. Some headlamp systems have a relatively simple construction, with the housing designed to be held in place by a few bolts next to the grille. In contrast, more complex systems may require removing the bumper and securing the housing with over a dozen bolts.

Headlamp housings can be made of plastic or metal. However, in the automotive industry, plastic is often preferred due to its favorable properties, including mechanical strength, crack resistance, chemical resistance to acid and alkali corrosion, and lightweight. There are many types of plastic materials available, allowing for the selection of the appropriate material based on the temperature and impact requirements of the application. In the manufacturing of prototype headlamps, the housing is typically made of ABS (Acrylonitrile Butadiene Styrene) or PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) due to their properties of dimensional stability and heat resistance.

Conclusion

The headlamp system is the most recognizable and unique element in an automobile’s appearance. In addition to common materials like ABS, PC, and aluminum, the current market is increasingly incorporating many new materials. The integration and design of all components of the front lighting system need to be unified to ensure safety, provide driver comfort, and comply with regulatory standards.

At AS Prototypes, we are dedicated to offering more solutions to help you increase productivity and reduce engineering development time. We can evaluate material properties early on, enabling us to take your CAD designs from initial concept through to prototype and mass production.