Artificial Intelligence (AI) is increasingly recognized as a powerful driver of growth, particularly in the manufacturing sector. Unlike other industries, manufacturing stands to gain significantly from AI’s application. While CNC machining has long been a cornerstone technology in manufacturing, AI is poised to revolutionize these operations.

Is AI Transforming CNC Manufacturing?

AI has moved beyond academic research, with machine learning and deep learning becoming mainstream technologies that many organizations are eager to leverage. This shift is set to positively impact various industries, including manufacturing, by driving the fourth industrial revolution, known as “Industry 4.0.”

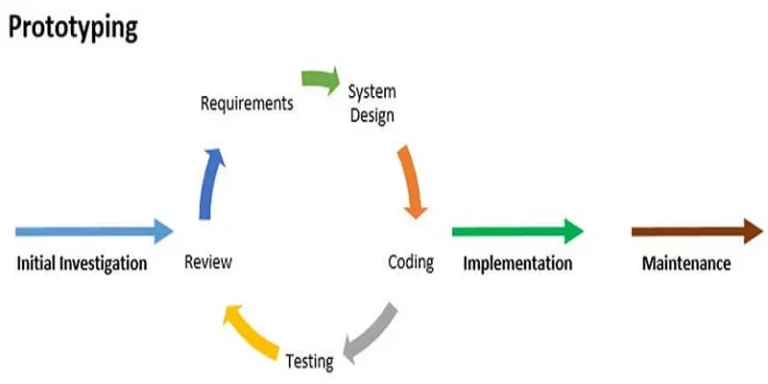

Rather than conjuring images of super-intelligent robots taking over, AI involves algorithms that optimize themselves through machine learning. This technology is set to transform prototyping and manufacturing processes, with CNC prototyping leading the charge.

How AI Enhances CNC Manufacturing

AI is already making significant strides in the manufacturing sector, reducing unplanned downtime and streamlining product design. Manufacturers are using AI-driven analytics to boost efficiency, quality, and safety.

Key Transformations in Manufacturing through AI

- Direct Automation: AI facilitates mass production by enabling robots to perform repetitive tasks, enhancing efficiency, automating solutions, and minimizing human error.

- Non-Stop Production: Unlike humans, who work in shifts, robots can operate 24/7, increasing production capacity to meet market demands.

- Safer Work Environments: With AI integration, fewer humans are required for hazardous tasks, reducing workplace accidents.

- Innovative Product Design: AI is revolutionizing product design through generative design software, where engineers input constraints and AI algorithms propose optimal solutions, tested through machine learning.

- Market Adaptability: AI is crucial in the Industry 4.0 revolution, extending beyond production to enhance supply chains by predicting market changes and enabling strategic planning.

Understanding CNC Machining

CNC (Computer Numerical Control) machining involves using pre-defined computer codes to control machinery like grinders, milling machines, and lathes. This technology is widely used in manufacturing for various tasks.

AI’s Impact on CNC Machining

Despite its potential for errors, CNC machining benefits from AI in several ways:

- Reduced Downtime: AI enables machines to self-diagnose and resolve faults, saving time and maintaining productivity.

- Machine Optimization: Advanced AI analyzes data to adjust machine settings for optimal performance, such as automatically altering pressure settings for better outcomes.

- Quality Control: AI ensures consistent output quality by monitoring and adjusting CNC machine operations, using software like Autodesk FeatureCAM to guarantee high-quality prototypes.

Conclusion

AI has the potential to enhance human capabilities and enable businesses to operate more efficiently. In the CNC manufacturing sector, AI addresses critical challenges such as expert shortages, integration issues, and information overload. By linking prototype manufacturing with cloud computing and AI-driven optimization, diagnostics, and self-modification, the future of CNC manufacturing looks promising with AI’s support.