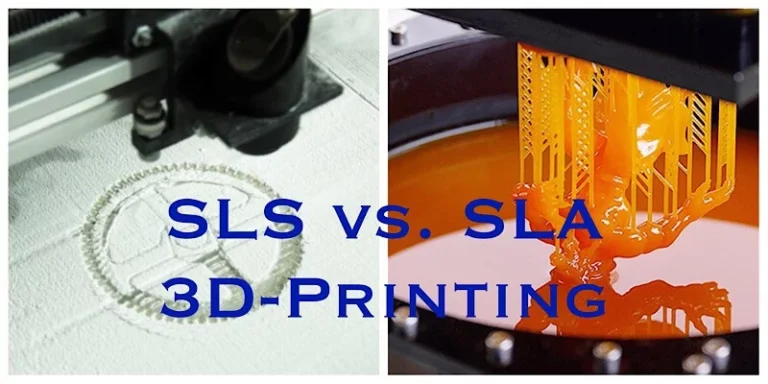

In recent years, the field of 3D printing has seen an increasing array of technologies such as SLA, SLS, SLM, FDM, DLP, MJM, and more. It is inevitable that 3D printers based on different technologies are compared. Today, let’s compare 3D printers based on FDM, DLP, and SLA technologies.

Basic Principles

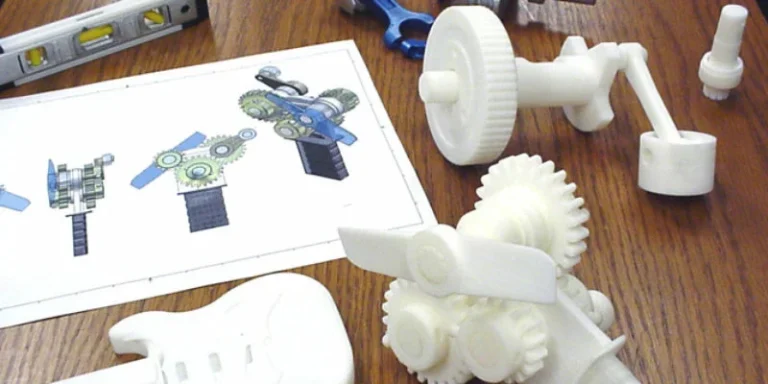

- FDM (Fused Deposition Modeling): This technology involves heating materials like ABS or PLA until they melt, then extruding them layer by layer through a nozzle, much like squeezing toothpaste, until the object is formed.

- SLA (Stereolithography): This technique uses a laser to trace the shape of each layer on the surface of a liquid resin. After each layer is traced, the build platform descends slightly (between 0.05-0.025mm), allowing the solidified layer to submerge into the liquid resin for the next layer. The resin used is photosensitive and solidifies upon exposure to the laser.

- DLP (Digital Light Processing): Similar to SLA in using photopolymer resins, DLP differs by utilizing a digital light projector instead of a laser. This allows DLP to cure a whole layer at once, whereas SLA builds by tracing with a single laser point.

Print Size

- FDM 3D Printers: These are flexible in architecture, ranging from XYZ frames to delta structures and even robotic arms, allowing for both small and large build sizes. However, large FDM printers often suffer from stability issues and slow printing speeds. Without substantial technical expertise, building large-scale FDM printers can be challenging.

- SLA: Also uses a moving light axis for printing and theoretically can achieve large sizes, but the speed would be slow, and current technology limits the production of large-scale SLA 3D printers.

- DLP: Increasing the size can compromise precision.

- Current print size comparison: FDM > SLA ≈ DLP.

Precision

- **3D printers control precision with XYZ axes, where Z-axis is the stepper motor’s precision, often referred to as layer thickness, which can theoretically go as low as 0.01mm. The main differences lie in the precision of the X and Y axes.

- FDM: The step-by-step extrusion process leads to a visible stair-stepping effect and requires high mechanical precision. Theoretically, smaller nozzles can achieve higher precision but are also prone to clogging.

- SLA and DLP: Both offer higher precision due to photopolymerization. DLP’s light is fan-shaped and scattered, whereas SLA uses a laser, which is nearly a straight line, thus providing better precision.

- Current precision comparison: SLA > DLP > FDM.

Machine Price

- **Generally, FDM printers are cheaper than SLA and DLP, ranging from $200 to $2,000, with some equipment costing over $2,000.

- **SLA and DLP machines are more expensive due to their high precision and industrial applications.

- Current price comparison: SLA > DLP > FDM.

Material Cost

- **FDM machines are more common, and their materials are relatively inexpensive, costing between $7 to $30 per kilogram of ABS material (depending on quality).

- **SLA and DLP materials are more expensive, with photopolymer resins costing between $60 to $450 per kilogram.

- In terms of material costs: SLA ≈ DLP > FDM.

Summary

- Build Size: FDM > SLA ≈ DLP

- Precision: SLA > DLP > FDM

- Machine Price: SLA > DLP > FDM

- Material Cost: SLA ≈ DLP > FDM

If there is anything we can help you, please feel free to let us know!