CNC Auto Services offer a level of customization and repair that goes beyond traditional auto services. While standard services handle routine maintenance and repairs, CNC Auto Services utilize advanced manufacturing equipment to create custom parts and solutions. This is particularly useful for older cars with hard-to-find parts or for customers seeking unique customizations.

How CNC Auto Services Enhance Your Vehicle

Think of CNC Auto Services as the “Pimp My Ride” of the auto repair world. They not only repair and replace parts but can also manufacture custom components tailored to your vehicle. This capability is invaluable for customization and for maintaining older vehicles when spare parts are scarce.

Steps in Custom Auto Part Development

1. Reverse-Engineering the Original Part

To replace or customize a part, the first step is reverse-engineering. This involves accurately measuring the existing part to ensure a perfect fit. Depending on complexity, different measurement methods are used:

- Simple Measuring Tools: For basic geometries like threaded holes.

- Coordinate Measuring Machines (CMM): For complex, curved surfaces.

- 3D Optical Scanners: For rapid, precise measurements without contact.

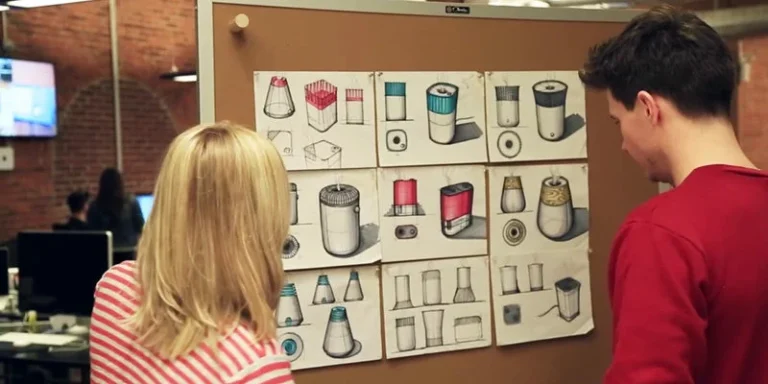

2. Design Verification and Prototype Manufacturing

Once measurements are complete, the new part is designed. For custom designs, collaboration with the CNC auto service ensures manufacturability. Sketches and engineering drawings are refined into a final design.

- Verification Prototype: Before full manufacturing, a 3D-printed prototype may be created to confirm fit and aesthetics, typically taking 1-2 days.

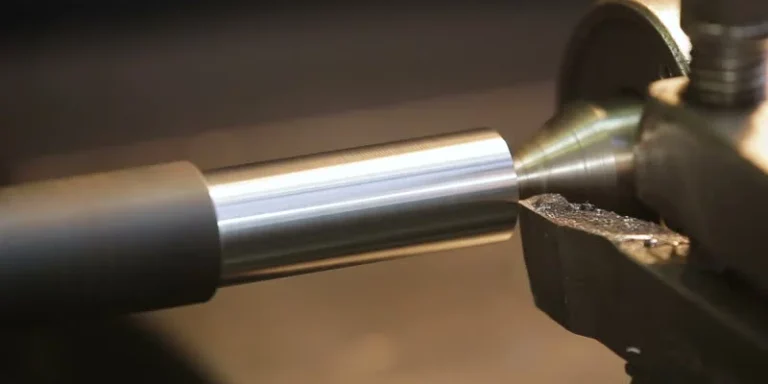

3. Custom Part Manufacturing

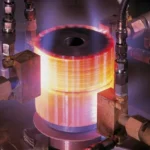

Most custom automotive parts are made from metal, such as aluminum or steel alloys. For low-volume production, 5-axis CNC machining is ideal due to its versatility and precision.

- 5-Axis CNC Machining: This advanced technology allows for the creation of complex parts with intricate designs and mirror-like finishes, such as custom car lamp lenses and steering wheels.

4. Prototype Fitting and Testing

Custom parts require fitting and testing to ensure functionality and fit. Unlike mass-produced parts, custom components may need manual adjustments. Technicians will test the part under various conditions to ensure it performs as expected.

Conclusion

CNC Auto Services provide a unique blend of repair, customization, and manufacturing capabilities, offering solutions that traditional auto services cannot. Whether you’re preserving an older vehicle or creating a one-of-a-kind custom car, CNC Auto Services can enhance your vehicle’s performance and aesthetics.