Lighting Prototyping and Manufacturing

Prototyping and rapid manufacturing are essential components of the lighting product design and development process. These methods allow for the quick creation of prototype and small-batch production parts for laboratory testing, performance evaluations, and ultimately, market launch, accelerating the entire path from initial design to commercial availability.

The Critical Role of Prototyping and Quick Production in Lighting Development

Developing new lighting products can often be a costly and time-consuming endeavor. However, contemporary approaches in moving from design to deployment are transforming how these products reach the market, with a focus on enhancing both efficiency and cost-effectiveness.

Rapid prototyping and manufacturing services provide a swift, reliable, and economical method to produce both prototype models that preserve critical features and small-scale production parts for concept validation and market testing of lighting solutions. This strategy enables the exploration of innovative designs, the gathering of early consumer feedback, and the development of tailored solutions for specific environments. These prototypes can then be tested under controlled laboratory conditions or in situ evaluations, accelerating their launch into the marketplace. Furthermore, this phase offers vital insights into future production techniques, cost estimates, timeline management, and quality assurance practices.

Optimal Strategies Enhanced by Prototyping and Manufacturing in Lighting Development

Proof of Concept:

Develop concepts for lighting systems into a feasible scope, focusing on defining essential details and fully understanding the design intent through proof-of-concept prototypes.

Visual Presentation:

Visual presentation models enable designers to demonstrate the appearance and aesthetics of their lighting designs to colleagues, clients, and stakeholders, thereby eliciting clear and actionable feedback.

Functional Prototyping:

Functional prototyping in lighting development, also known as Beta prototyping, allows for testing the form, fit, and function of lighting components. This process aids in refining design iterations and enhancing the overall performance of the lighting systems. It enables the identification and resolution of issues early in the development cycle, significantly reducing business risk before the final product is completed.

Engineering Validation:

Developing engineering prototypes that closely mirror the final lighting product simplifies the process of verifying design, engineering, and manufacturability. This step is essential before committing significant resources to costly tooling and production processes.

Pilot Production:

Rapid manufacturing and custom low-volume production of lighting systems act as an effective bridge from prototype to full-scale production. This approach speeds up market entry and maintains cost-efficiency, facilitating a smoother transition to commercial availability.

Get in Touch to Develop Your Custom Lighting Components and Prototypes

We specialize in offering solutions for lighting component development, focusing on manufacturability and cost-efficiency from initial concept to production.

Lighting System Prototyping and On-Demand Manufacturing by AS Prototypes

With deep expertise, AS Prototypes excels in lighting system prototyping and machining, serving numerous lighting manufacturers worldwide. We support you at every stage—from initial prototyping, through testing and iterations, to product demonstrations, and even into short or low-volume production runs.

Our prototyping and manufacturing capabilities are extensive, featuring an in-house CNC machining and finishing shop, 3D printing, urethane casting, rapid injection molding, and sheet metal fabrication to meet all your lighting development needs.

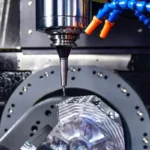

CNC Machining for Lighting Components

CNC machining is a vital technology in the lighting industry, enabling the precise and efficient production of intricate components crucial for various lighting applications. At AS Prototypes, we specialize in CNC machining, utilizing premium materials such as aluminum and polycarbonate to meet exacting specifications with high tolerances. This capability ensures that our machined parts, including lighting fixtures and enclosure systems, meet the demanding standards of the lighting sector.

Typical applications: Lighting Fixture Housings, Heat Sinks, Reflectors, Optical Lens Frames, and Mounting Brackets.

Typical materials: Aluminum, Polycarbonate, Acrylic, Stainless Steel, and Ultem.

3D Printing for Lighting Components

3D printing is transforming the lighting industry at AS Prototypes by enabling the rapid production of complex, customized components such as bespoke lighting fixtures, intricate decorative elements, and precisely engineered optical components. We specialize in utilizing industry-specific materials to ensure each product not only meets precise specifications but also adheres to the high-quality standards required in lighting applications.

Typical applications: Light Fixture Housings, Custom Lamp Shades, Optical Lens Frames, Heat Sinks, Decorative Elements, Mounting Brackets, and Reflectors.

Typical materials: Acrylic, Aluminum, and ABS.

Get in Touch to Develop Your Custom Lighting Components and Prototypes

We specialize in providing solutions for lighting component development, emphasizing manufacturability and cost-efficiency from concept through to production.

Vacuum Casting for Lighting Components

Polyurethane casting offers numerous benefits and applications, making it a valuable technique for the lighting industry, especially for low-volume production of lighting component housings. This method is ideal for initial product launches before investing in injection molding and tooling, allowing for market research and gathering customer feedback. It also facilitates the early delivery of lighting components. In markets characterized by rapid innovation and short product lifecycles, silicone molding used to cast urethane enables manufacturers to quickly iterate and refine their designs without the need to recoup the costs associated with hard tooling.

Typical applications: Light Fixture Housings, Decorative Elements, Custom Lamp Bases, and Diffusers.

Typical materials: Polyurethane, Epoxy Resins, and TPU.

Rapid Injection Molding for Lighting Components

Rapid injection molding is an optimal solution for lighting manufacturers requiring low-volume molded parts. It effectively supports manufacturability analysis, engineering tests, product evaluations, investor demonstrations, and readiness for production in the advanced phases of lighting component development. Additionally, it serves as an intermediary between prototyping and full-scale production, allowing for the early detection and resolution of issues before transitioning to manufacturing.

Typical applications: Light Fixture Housings, Diffuser Panels, Mounting Brackets, Decorative Elements, and Switch Covers.

Typical materials: Polypropylene, Polycarbonate, Polyethylene, ABS, and Acrylic.

Sheet Metal for Lighting Components

Sheet metal fabrication is a critical technique in the production of lighting components, emphasizing precision and adaptability. This process involves cutting, bending, and assembling metal to create parts for devices ranging from lighting fixtures to enclosures for electrical components. The ability to meet exact specifications and maintain high tolerances makes sheet metal ideal for complex lighting applications. Additionally, materials like aluminum used in this process are lightweight and corrosion-resistant, supporting the durability and safety standards required in lighting settings.

Typical applications: Fixture Housings, Reflectors, Mounting Brackets, Decorative Elements, and Heat Sinks.

Typical materials: Aluminum, Stainless Steel, and Brass.

At AS Prototypes, we are dedicated to collaborating with you to ensure the success of your entire lighting project. Whether you need prototypes, custom components, or mass-produced parts, we deliver reliable and consistent results, always adhering to your schedule.