One of the main challenges product designers face is the inability to effectively demonstrate how their envisioned design prototypes will look in real life. This is where prototype engineering plays a crucial role. However, this complex process requires extensive testing and scientific research from various engineering disciplines.

Why Prototype Engineering is Necessary

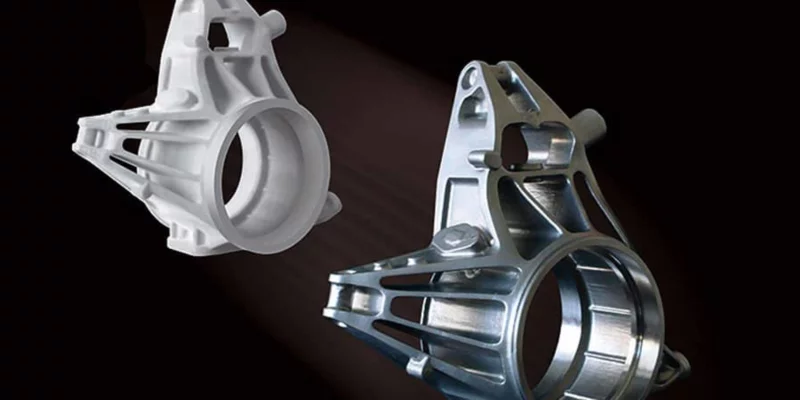

Prototype engineering involves creating a working model of a solution or design, serving as a crucial step in final product development. By developing multiple prototypes, designers can explore various iterations of a product and assess its appearance and performance in real life. Through the process of trial and error, designers and engineers can identify the best prototype to advance to final production.

Prototype manufacturing and rapid manufacturing offer numerous benefits that surpass those of other engineering techniques. Some of the key advantages include:

1. Ability to Make Changes Almost Instantaneously

Once prototype development is complete, a physical model of the concept is available for visual assessment. This allows for immediate changes based on customer feedback, enabling multiple iterations before finalizing the design for production. Such iterations enhance the product’s efficiency and overall quality compared to the initial version.

Having a tangible prototype instills confidence in both designers and customers. It also provides a clearer understanding of market demand and needs, facilitating the creation of a competitive product with a higher acceptance rate.

2. Time and Cost Efficient

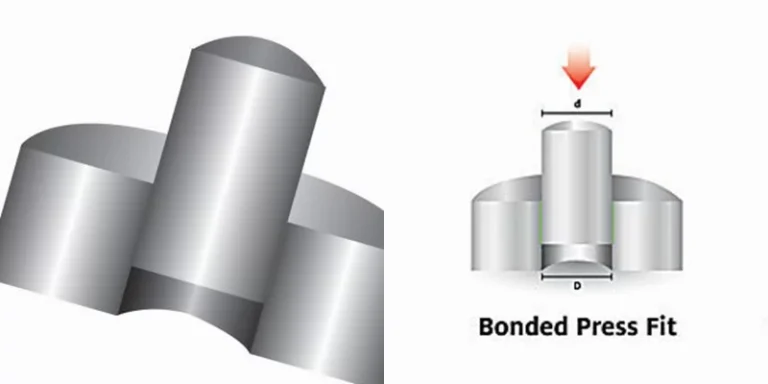

Prototype design and manufacturing save significant time and costs. The need to create new patterns and molds for each prototype is eliminated, primarily due to rapid manufacturing techniques like CAD design and 3D modeling. These methods are not only fast but also cost-effective, minimizing raw material waste. In many cases, any excess material can be reused.

Identifying design issues early allows for corrections before final production. Without a prototype, moving directly to production could result in a batch of products with the same flaws, leading to waste and disappointment for both the manufacturer and consumers.

3. High Customization

One of the key benefits of prototype engineering is the high level of customization it enables. Each prototype can be modified in shape and design, allowing even complex concepts to be realized. Once approved, these prototypes can be developed into final products.

Modern prototyping techniques utilize CAD to create virtual models, making it easy to adjust geometries without affecting other components. This flexibility allows prototypes to be tailored precisely to meet specific requirements.

3D printing of a human face

4. Realization of the Design Concept

Prototype design allows designers to bring their concepts to life beyond virtual visualization. The tangible look and feel of a prototype enable designers and engineers to gain a deeper understanding of how the final product will appear in production.

This realization is crucial for stakeholders and the public, as it fosters confidence and a personal connection to the final product. Additionally, it helps designers and engineers claim ownership of their designs, reducing the risk of competitors copying their concepts.

CNC Milling of a Mustang GT car logo

5. Minimized Design Flaws

Creating prototypes before final production helps identify and correct design flaws early in the process. While some issues may be apparent in virtual designs, understanding how a product behaves in real-life scenarios is challenging without a physical model. Testing actual prototypes in various simulated environments allows for performance evaluation, significantly reducing the risk of usability issues and faults in the final product.

Modern Prototyping Techniques

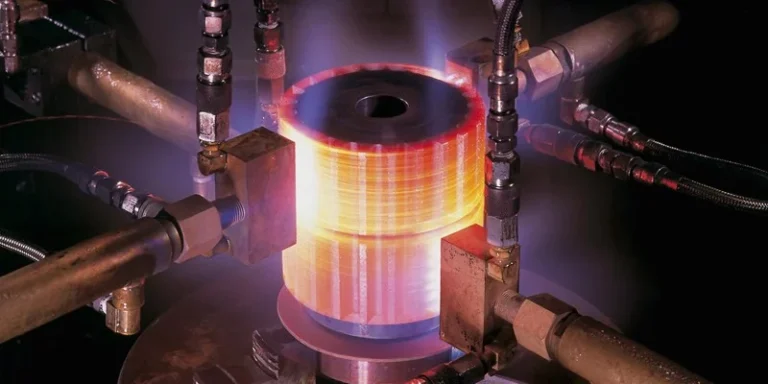

Technological advancements have revolutionized the prototyping and rapid manufacturing industry. With time and cost being critical factors for any company or designer, it’s essential that prototyping techniques are rapid, economical, and reliable.

Today, prototype development primarily utilizes CNC machining and 3D printing. Both techniques are CAD-controlled, allowing designers to first input their virtual designs into a computer, where modifications can be made based on user demands before creating a physical prototype.

CNC machining methods, such as milling and 5-axis cutting, are subtractive techniques, while 3D printing is an additive method. Each has its own advantages and disadvantages.

Prototype engineering is an effective way to establish a proof of concept and ensure that the product can withstand manufacturing challenges. Given its importance in the product development process, it’s advisable to work with a reputable prototype manufacturer like AS Prototypes.

AS Prototypes Offers Business Prototyping Partnerships

- Demonstration of Drafts for specific application fields.

- Integration of Components in advanced machining equipment and devices.

- Optimization of Product Design to create user-friendly models.

- Practical Prototypes that integrate materials, craftsmanship, and engineering expertise.

- Building Long-Term Relationships with small- and medium-sized companies and startups focused on product development.

The Team Offers Customized Engineering Prototypes

- Mechanical Design & Engineering using advanced CAD software.

- Support for Engineering & Design Verification Tests: EVT, DVT, PVT.

- Expert Advice on Components based on materials, processes, machining tolerances, and potential issues.

- Initial Operation, Proof, and Optimization in the design phase.

The Future Plan of Prototype Engineering

To assist more customers and designers in transforming their innovative research into market-oriented products, processes, and services, we aim to expand our engineering teams and enhance our R&D capabilities. Our goal is to bridge the gap between industry and product development, allowing more companies to access cutting-edge research through functional and efficient models and prototypes.

AS Prototypes has been in the prototyping business for decades, delivering quality prototypes to clients worldwide. If you are a designer, we invite you to partner with us and bring your ideas to life.