Plastic fabrication plays a vital role in the plastic industry and has been essential for many years. This blog explores various fabrication methods.

Plastic fabrication involves the design, manufacture, and assembly of plastic products through various processes. Custom plastic fabrication includes activities such as testing new plastics, engineering innovative products, and acquiring advanced machinery for improved and faster fabrication.

1. Blending/Compounding

Compounding is a plastic fabrication process where two or more plastics are melted and combined into a homogeneous mixture. Once blended, they can be shaped into new forms. This process requires precise specifications and quantities to ensure the final product meets desired characteristics. Similar to metal alloys, compounding enhances the performance of the final product. Common plastic compounds include:

- Basin Resin

- Blowing Agents

- Purge Compounds

- Flame Retardants

2. Molding

Molding is one of the oldest and most effective fabrication processes still widely used by custom plastic fabricators. It includes techniques such as injection molding, rotational molding, and blow molding, all of which are essential for plastic fabrication.

Small plastic pellets used in the molding process. They come in all different sizes and colours

- Injection molding

Injection molding is by far the most versatile molding technique out there. Injection molding incorporates different size of pressers which are dependent over the pressure and tonnage of the product. Injection molding can make big parts such as plastic car parts as well as small plastic components for surgical applications. Injection molding is a bit more expensive plastic molding technique and is only used for the manufacture of plastics requiring a high melt index.

- Compressed molding

The name of this molding pretty much explains itself. The heated plastic is placed inside a heated mold and is then compressed using high power pressers. Curing is followed to make sure that the product maintains its integrity and do not deform. Compressed molding is ideal for high-strength compounds such as thermosetting resin.

- Blow Molding

Plastic blow molding is similar to that of glass molding. A parison is first inflated with air. This air is then pushed against the plastic mold of the desired size. Once the mold is cooled, the plastic is ejected. Blow molding is pretty much straightforward and linear and can rapidly fabricate high volume, one-piece hollow objects. Plastic bottles, fuel tanks, and other cavity-based plastic components are mostly made via blow molding

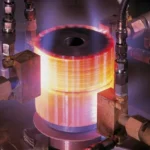

- Rotational molding

Rotational molding uses the rotational movement and high temperatures to coat the inside of a mold layer by layer which eventually forms the part. The constant rotation creates high centrifugal forces resulting in even-walled products. Rotation molding is used to make large hollow containers. Therefore, the rotation is not very fast. However, this process is economical for certain products and at times is cheaper than other types of plastic molding processes. A hollow plastic component such as buoys, fuel tanks, and canoes are all made via rotational molding. Another advantage of rotational molding is that there is very less waste material since the excess or run off plastic can be immediately used back in the fabricator.

Plastic tank like the one shown above are manufactured by rotational molding

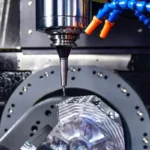

3.Plastic Extrusion

Plastic extrusion is a process used to create plastic sheets, tubes, and pipes. In this method, plastic is first melted and formed into small pellets, which are then forced through a die. Many manufacturers favor this technique for its speed, durability, and consistency. Additionally, extruded plastics can withstand stress better than other fabrication methods, as they lack seams.

Extruded plastic rods. They tend to have better strength since they do not have any seams

4.Thermoforming

Thermoforming is a fabrication process where thermoplastics are softened using heat and reshaped to create the desired products. This technique can involve various methods, such as bending plastic sheets over a strip heater or using vacuum forming to mold the parts. One of the advantages of thermoforming is its relatively low tooling costs compared to other fabrication methods, as thermoformed parts do not require treatment at high temperatures and pressures.

5.Die Cutting

Die cutting is an efficient technique for cutting plastic film and thin sheets into finished parts. Common materials produced through die cutting include polycarbonate film, polyester film, and HDPE sheets. This method ensures precision and consistency in shaping various plastic components.

6.Lamination

Lamination involves coating the outer surface of a product to protect it from external impacts and environmental damage. This process also enhances the product’s styling, appearance, and durability. Common materials used for lamination include synthetic resin and film. Typically, pressure and heat are applied simultaneously to ensure effective adhesion of the lamination material.

Synthetic resin lamination creates an adhesive layer between two substrates, while film lamination forms a plastic barrier on the product’s exterior. Common laminating materials include metal sheeting, paper, and flexible foam.

7.Welding

Welding is not limited to metal fabrication; it is also commonly used to bond thermoplastics that cannot be effectively joined with adhesives or other methods. Plastic welding encompasses various techniques, including hot plate welding, ultrasonic welding, speed tip welding, and hot gas welding. These methods ensure strong and durable bonds between plastic components.

8.Plastic Foaming

Plastic foaming produces plastic insulators that serve as excellent insulation for buildings. This fabrication process utilizes polystyrene and polyurethane to create foam. Synthetic foam is more durable than other types and offers superior insulation properties.

In China, there are many plastic fabrication companies. At AS Prototypes, we offer premium plastic machining services tailored to your fabrication needs. Whether you require prototypes or batch production, we are eager to help bring your ideas to life.