Modern industry is unimaginable without plastics. Today’s industrial-grade polymers are not only easy to manufacture and process, but they also boast significant strength, excellent corrosion resistance, and, most importantly, a much lower weight compared to any metal. These attributes make them highly favored among industrial designers. Consequently, plastic prototyping techniques have seen remarkable advancements over the past few decades. Let’s explore what these innovations can offer us now.

Plastic Prototyping Today

For a long time, plastic manufacturing was dominated by mass production techniques. This required an injection mold and a machine to inject the plastic into the mold, making the entire setup very costly. Any design changes to such a system were also expensive. As a result, metal remained the preferred material for prototyping, especially with the rapid advancements in digital systems and computer numerical control (CNC) machines. However, the advent of rapid prototyping processes has changed this landscape significantly.

The Development Of Rapid Plastic Prototyping

The first innovation was the introduction of vacuum silicone casting techniques, which replaced hard tooling with soft tooling. Silicone molds are significantly cheaper and easier to produce.

Following this, groundbreaking additive manufacturing processes emerged, eliminating the need for blanks or tooling altogether and offering unparalleled design flexibility.

Finally, advancements in CNC machining facilitated rapid plastic injection molding. Aluminum interchangeable molds, which are more manufacturable than traditional steel molds, can reduce tooling lead time by up to 60%. Additionally, modifying the cavity of an aluminum mold is much simpler than altering one made from heat-treated steel.

The Benefits Of Implementing Rapid Plastic Prototyping

Cost of Plastic Prototyping

Plastic materials are known for their low melting temperatures, ease of maintenance, and overall simplicity in processing, making plastic prototype production relatively inexpensive. If you’re working with a limited budget, you can easily create prototypes at home by purchasing some silicone, pouring it over a master model (which can be made manually), waiting for it to set, and then casting the parts yourself.

Durability

Plastic materials are highly durable, offering excellent stability, fatigue strength, and friction properties. However, it’s important to protect them from UV light and low temperatures, as some polymers can become brittle under these conditions.

Reliability

Plastic prototyping processes are well-established, with numerous professional injection molding services utilizing these techniques daily. If you’re unsure about the best method to use or how to execute it, you can always seek advice from experts in the field.

Recyclability

The era when plastic pollution was a major ecological issue has passed. Modern industrial plastics are designed to be recyclable, and their production processes generate minimal harmful waste.

Lead Time

Modern rapid prototyping techniques are ideal for producing low-volume batches of plastic parts. In some cases, you can receive your prototype within a week by ordering from injection molding services. This quick turnaround is possible because plastic prototyping typically requires very little post-processing.

Where Plastic Prototypes Can Help

Plastic prototype parts are utilized in a wide range of applications beyond just kitchenware and home appliances. For instance, numerous medical-grade products are made from plastic because certain polymers are biocompatible with human tissue and are very lightweight. Transparent plastic components are extensively used in automotive lighting due to their durability and reduced brittleness compared to glass. Many plastics offer excellent insulation and heat resistance, making them ideal for handles and enclosures on products with heated surfaces or high voltage, thereby ensuring user safety. Additionally, some polymers possess favorable friction properties, making them suitable for manufacturing cost-effective and efficient bearings.

The Top 4 Types Of Rapid Plastic Prototyping Options

With the rapid advancements in the manufacturing industry, technologies such as casting, 3D printing, injection molding, and CNC machining have become increasingly prominent. These quick-turn, 3D CAD-based prototyping tools are now widely utilized in the production of plastic parts.

1.Casting techniques for plastic prototype manufacturing

Silicone casting is an excellent method for low-volume plastic prototype fabrication as it involves creating molds from a master model (a sample). Typically, the master model is suspended over an empty tank. Technological elements, often made of plastic, are then added to the model, such as channels for pouring plastic and ventilation systems. Liquid silicone is poured into the tank and allowed to solidify, sometimes with additional curing in an oven. Once the silicone has set, the mold is split in half and can be used to produce up to 25 plastic parts. This process requires no capital investment.

2. How to use 3D-Printing for plastic prototyping

Additive manufacturing, commonly known as 3D printing, is a relatively innovative process for producing various parts. Unlike traditional manufacturing, where the blank is typically larger than the final part, 3D printing involves building the part from a blank that starts as either powder or a thin filament. This material is applied to the printer’s base plate layer by layer and is sintered or cured to match the current cross-section of the part. Since its inception in the 1980s, additive manufacturing has made significant advancements in precision, surface finish, material selection, and lead time.

Selective Laser Sintering(SLS)

Selective laser sintering (SLS) is one of the pioneering techniques in additive manufacturing, particularly for rapid plastic prototyping. It stands out as one of the most versatile additive processes, capable of working with a wide range of materials, including plastics. Plastics, in particular, benefit from SLS because they require relatively low laser power to sinter. A key advantage of this process is that the powder spread over the base plate acts as a support structure for overhanging elements, enhancing the stability and precision of the final product.

Fused Deposition Modelling(FDM)

Fused Deposition Modeling (FDM) is the most affordable and straightforward additive manufacturing process for producing plastic prototypes. Many hobbyists even build FDM 3D printers at home. This technique uses raw material in the form of a plastic filament, which is melted and deposited layer by layer to form the part’s cross-section. Overhanging structures are supported by a secondary, more brittle plastic that can be easily removed after printing. While FDM is cost-effective, it typically results in the poorest surface finish and quality, necessitating additional post-processing if aesthetics are a priority.

Stereolithography(SLA)

Stereolithography (SLA) is often regarded as the pioneer of all 3D printing processes and is known for producing parts with the highest quality. The surface finish achieved with SLA is nearly flawless, and the precision is primarily constrained by the diameter of the UV or laser light used. This process is extensively utilized for creating master models for future casting and prototypes where aesthetics are crucial. However, SLA is also the most expensive 3D printing method due to the high cost of the liquid polymer and the need to fill the tank with a substantial amount of it. Another drawback of SLA is the support structures, which must be made from the same material as the model and require mechanical removal. This can leave blemishes on the surface that necessitate further post-processing.

Multijet Printing(MJP)

Multijet Printing (MJP) is a popular choice for producing plastic prototypes, combining many of the advantages of FDM with fewer drawbacks than the SLA process. MJP works by melting raw plastic into droplets and dispensing them from the printer’s nozzle in the required contour. One of the key advantages of MJP is that it delivers part quality comparable to SLA without the need to fill an entire tank with liquid polymer, thus avoiding the issue of excess material. Additionally, MJP stands out as the only multicolor process among the mentioned methods, offering greater versatility in prototype design.

Post-processing of 3D-printed prototypes

Despite the advancements in Additive Manufacturing, many plastic parts still require post-processing. The most common methods include machining, polishing, and chemical treatments.

- Machining: This straightforward technique involves placing the manufactured part into a machine tool and processing it with a mill to achieve the desired shape and finish.

- Polishing: A well-known process that uses a special paste and a polishing instrument to achieve a perfect surface finish.

- Chemical Processes: These include acetone processing and coating:

- Acetone Processing: This method uses gaseous acetone to melt the surface of the part, making it smoother. While highly effective, it is suitable for only a limited number of polymers.

- Coating: This more universal method involves covering the part with paint or another material to enhance surface quality.

3. How to create a plastic prototype with rapid injection molding

Rapid plastic injection molding is a variation of conventional injection mold manufacturing technology, distinguished by several key details. One significant difference is that rapid molds have more joints. The mold cavity is connected to the base, allowing for easy modifications: you can simply remove and change the cavity without altering other elements. This design increases flexibility but may reduce accuracy. Additionally, instead of using hardened steel, which is suitable for millions of iterations, rapid molds use aluminum alloys. Although less durable, aluminum alloys are up to five times easier to manufacture. These modifications make plastic injection molding viable even for prototypes, though it is advisable to reserve this process for high-quality works due to its relatively high cost.

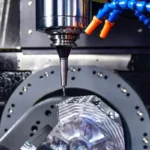

4. When using CNC machining to create plastic parts

When it comes to machined plastic and metal components, many plastic prototype manufacturers rely on CNC machining for form, fit, and functional testing due to its numerous advantages in the prototyping realm. CNC machining allows for the use of production-grade materials, enhancing the accuracy and quality of prototypes. At Wayken, we utilize CNC prototyping to create both plastic prototypes and metal parts. This approach enables your design team to closely simulate the final product’s appearance and function, validate assembly work, and provides the necessary time and flexibility to modify and optimize the design.

The Future Of The Rapid Plastic Prototyping Technology

In the future, many professionals predict that additive manufacturing (AM) will occupy an even larger portion of the prototyping market. This technology is ideal for prototyping, especially with ongoing advancements aimed at increasing printing speed and part quality. Currently, issues such as porosity are being addressed through extensive research, and overcoming these imperfections could make AM the perfect choice for plastic prototyping within the next decade—unless a new innovative process emerges. For more information on our capabilities, you can explore our plastic machining services.